|

氢与燃料电池技术

Technologies for Hydrogen & Fuel Cells

作为面向各种流体和气体处理应用的工程组件和系统的全球领先制造商,Parker拥有成功帮助客户将新技术推向市场的良好记录。

随着氢气的发展势头强劲,并被视为未来的主要能源,Parker能够很好地支持新的应用-从处理和隔离气体到运输,存储和分配,再到各种形式的终使用。

我们为氢应用开发先进的产品和技术,以提高效率,降低成本并确保安全。利用我们在其他市场领域的专业知识,我们还可以转让现有技术来提供氢气Hydrogen-Ready products解决方案。与从头开发组件相比,在不同市场和应用程序之间重新设计组件可以更便宜,更快。

在我们的博客中了解技术转让如何促进产品开发,该博客考虑了技术转让对氢应用的价值。

氢气行业-Hydrogen Industry的产品和服务

无论是专门为氢气应用而设计,还是从其他行业进行了重新设计,我们的产品都具有很高的可靠性和耐用性。

借助可承受极端寒冷,高温和腐蚀性介质的接头,以及在关键应用中防止液体冻结的软管,我们的氢Hydrogen-Ready Products产品包括管道,过滤组件,控制阀,干燥器,压力调节器和传感器,密封件,管道,加热的软管,冷却器,资产管理工具和大口径非焊接管道解决方案。 Our hydrogen-ready products include tubing, filtration components, control valves, dryers, pressure regulators and transducers, seals, tubing, heated hoses, chillers, asset management tools and large bore non-weld piping solutions.

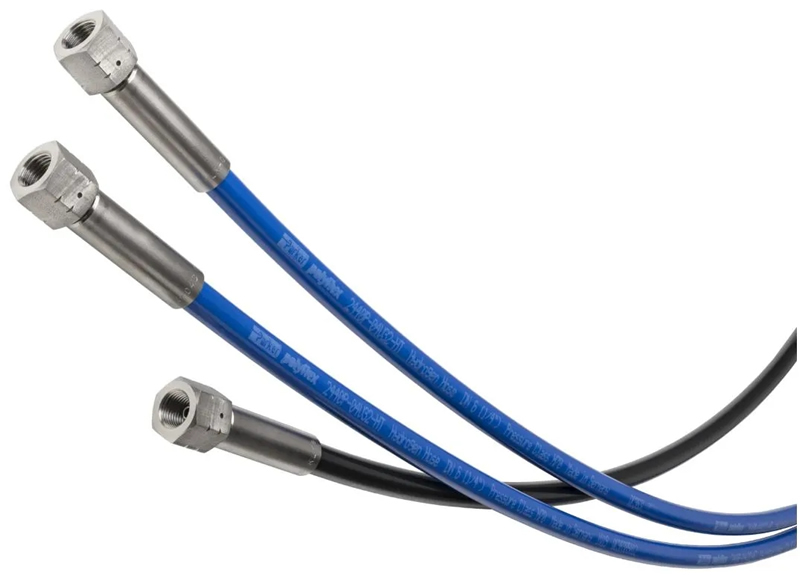

热塑性软管 - Thermoplastic Hose

派克的氢气软管旨在满足高压氢气传输的挑战性要求,提供快速加油且在-40°C时无泄漏的预冷氢气。坚固的设计提供了很高的可靠性,并延长了在100 bar氢燃料站中使用的使用寿命,弯曲半径小,可以在有限的空间内更方便地使用和安装。

加热软管 - Heated Hose

氢溶液通常存在于其他市场和应用中。Parker的电加热软管和管毯初是为了防止柴油机尾气在柴油后处理应用中冻结而创建的。该技术已在氢气市场中采用,以阻止水冻结的副产品,保持排气管线的运行,帮助保持恒定的环境温度并减少停机时间和维护。

请参阅原始应用程序中有关产品信息的链接:

SCR软管

定制加热软管

管接头和阀门 - Tube Connections and Valves

安全有效地连接氢气管道和管道至关重要,Parker继续引领设计优化燃料输送的产品。螺母和套圈类型的接头以及我们的平面密封品种均获得EC79认证。这突出了它们在车载应用中的能力和耐用性,因此可以安全地对其进行重新设计,以用于静态氢系统中。

我们提供有关安全使用和安装这些产品的认证培训。

Instrumentation Products

Seal-Lok Technology

博客:Seal-lok ORFS CNG配件通过了车辆防火安全测试

低压接头 - Low Pressure Fittings

配件和连接器通常仅被视为商品零件,但是配件却面临着自身的工程挑战,尤其是在关键应用中以及通过腐蚀性材料时。派克的塑料低压接头具有很强的耐碱性,可在较宽的温度范围内使用,以确保安全性和较长的使用寿命。我们的不锈钢接头对低压气体具有出色的密封性能。

塑料低压接头

不锈钢配件

过滤 - Filtration

在氢气应用中,过滤在确保达到清洁度至关重要。派克的过滤和气体制备解决方案可净化水并去除压缩机油,碳氢化合物和湿气,以确保清洁的氢气生产,同时保护关键部件。

过滤产品

样品过滤器

HYG Option 氢用选项

HYG氢用选项 更换了阀杆、填料和材料。包装材料为聚四氟乙烯玻璃PTFE-Glass。阀秆经过增强,特殊硬化。HYG使阀门适用于低至零下73度。气阀门在装运前经过100%氦气测试。阀门寿命45000循环。该HYG选项选件设计用于驱动阀,但也适用于手动阀。单向阀和安全阀。HYG Change the stem, packing and material. The packing material is PTFE-Glass. The stems are upgrated, special hardening. HYG make the valve suitable for use down to zero 73. 100% helium seat tested prior to shipment. Go beyone 45000 cycles befor first leakage. This option was designed for actuated valves, but also good for manual valves. check and relief valve.

型号 |

产品描述 |

| CXF6-5-HYG |

Line filter hydrogen service |

| CXO4400-HYG |

Check valave o-ring hydrogen |

| CXO9900-HYG |

Check valave o-ring hydrogen |

| RSM607-O1SHYG |

Vave R/Kit 20SM6071727374-O1S |

| RSM907-O2SHYG |

Valve repair kit |

| 10RVP9072-HYG |

Relief valve assy helium tested |

| 101B-6322-HYG |

Plug 10RVP - Insp for HYG service |

| 102B-6324-HYG |

Seat 10RVP - INSP for HYG service |

| 20SM4071-HYG |

Valve assembly hygrogen service |

| 20SM6071-C1SHYG |

air valve assy |

| 20SM6071-O1SHYG |

air valve assy |

| 20SM6072-O1SODBHYG |

Obsoleter use 20SM6072-O1SODHYG |

| 20SM6072-O1SODHYG |

Valve assy - OD-Hydrogen service |

| 20SM6072-O1SWOA-HYG |

air valve assy |

| 20SM9071-HYG |

Valve assembly hygrogen service |

| 20SM9071-O1SODHYG |

Air valve - o1s outdoor / HYG service |

| 20SM9071-O2SODHYG |

Air valve - o2s outdoor / HYG service |

| 20SM9072-O2SODHYG |

Air valve - o2s outdoor / HYG service |

| 30VM4081-FRC1LTHYG |

valve assembly |

| 30VM4081-FRC1XHYG |

valve assembly |

| 30VM4081-O1SLTHYG |

air valve low temp hyg service |

| 6MP7-MACL-20-TO-SS-HYG |

check valve o-ring 3/8in hydrogen |

| 6MP7-MANAB-TGSS-C1SOD-HYG |

air valve 3/8 in MPI Hydrogen |

| 6MP7-NANAB-TGSS-O1SOD-HYG |

Two way angle w/O1S Hydrogen |

| 6MP7-MANLR-TG-SS-HYG |

Medium pressure needle valve |

| 60VM6081-FRC1XHYG |

valve assembly |

Technologies for Hydrogen & Fuel Cells

As a world-leading manufacturer of engineered components and systems for a wide range of fluid and gas handling applications, Parker has an established track record of successfully helping customers bring new technologies to market.

With hydrogen gaining momentum and seen as a leading energy source for the future, Parker is well positioned to support the newest applications – from processing and isolating the gas to transportation, storage and dispensing, right through to final use in its various forms.

We develop advanced products and technologies for hydrogen applications that increase efficiency, reduce cost and ensure safety. And using our expertise in other market sectors, we can also transfer existing technologies to provide hydrogen-ready solutions. Re-engineering components between different markets and applications can be cheaper and faster than developing them from scratch.

Find out how technology transfer can accelerate product development in our blog which considers the value of technology transfer for hydrogen applications.

Products and services for the hydrogen industry

Whether designed specifically for use within hydrogen applications or re-engineered from other industries, our products offer high levels of reliability and durability.

With fittings that can withstand extreme cold, heat and aggressive media, and hoses that prevent liquids from freezing in critical applications, our hydrogen-ready products include tubing, filtration components, control valves, dryers, pressure regulators and transducers, seals, tubing, heated hoses, chillers, asset management tools and large bore non-weld piping solutions.

PRODUCT SPOTLIGHTS

Thermoplastic Hose

Parker’s hydrogen hose is designed to match the challenging demands of high pressure hydrogen transfer providing fast refuelling and no leakage for pre-cooled hydrogen at -40 °C. The robust design offers a high level of reliability and an extended life cycle for use in 100 bar hydrogen fuel stations, and the tight bend radius enables more convenient usage and installation in limited spaces.

Product Overview

Heated Hose

Often hydrogen solutions exist in other markets and applications. Parker’s electrically heated hoses and tube blankets were originally created as a response to prevent Diesel Exhaust Fluid from freezing within diesel after-treatment applications. The technology is being adopted within the hydrogen market to stop the by-product of water freezing, to keep vent lines running, help in a constant ambient temperature and reduce downtime and maintenance.

See the links for the product information in its original application:

SCR Hoses

Custom Heated Hoses

Tube Connections and Valves

Safely and effectively connecting hydrogen pipework and tubing is crucial and Parker continues to lead with the way with products engineered to optimise fuel conveyance. Both nut and ferrule type fittings and our flat face sealed varieties have EC79 approvals. This highlights their capability and robustness in on-vehicle applications and they can therefore be safely re-engineered for use within static hydrogen systems.

We offer certified training on the safe use and installation of these products.

Instrumentation Products

Seal-Lok Technology

Blog: Seal-lok ORFS CNG Fittings Pass On Vehicle Fire Safety Test

Low Pressure Fittings

Fittings and connectors are often viewed simply as commodity parts, yet fittings have their own engineering challenges especially in critical applications and when passing corrosive materials. Parker’s plastic low-pressure fittings are strong alkaline-resistant with a wide temperature range to ensure safety and a long service life. Our stainless-steel fittings have excellent sealing properties for low pressure gases.

Plastic Low Pressure Fittings

Stainless Steel Fittings

Filtration

Within hydrogen applications, filtration plays a crucial part in ensuring that cleanliness levels are met. Parker’s filtration and gas preparation solutions purify water and remove compressor oils, hydrocarbons and moisture to ensure the cleanest production of hydrogen while protecting critical components.

Filter Products

Sample Filters

|