|

|

|

|

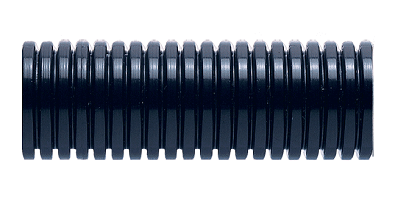

HTC conduit is suited to static and dynamic applications where elevated temperatures are present. HTC is resistant to all under bonnet greases, fuels and oils.

Features & benefits:

- Very high flexibility & fatigue life

- Very high elevated temperature, abrasion, impact and shock resistance

- Temperature range: -40oC to +175oC

Temperature range short-term: +190°C

- UV Resistance - Very high

- IP40 (TempGuard & standard hinged fittings) IP67 (Sealed fittings)

- Self extinguishing, low smoke toxicity & halogen free

Conformity

- CE Mark to the low voltage directive

- RoHS Compliant to 2011/65/EU

- Conforms with end of life vehicle directive (ELV) EU200/53/EC

| HTC08 |

08 |

7.5 |

9.8 |

6.2 |

20 |

50 |

| HTC10 |

10 |

8.5 |

11.5 |

8.7 |

15 |

50 |

| HTC12 |

12 |

10 |

13.0 |

9.4 |

25 |

50 |

| HTC16 |

16 |

13 |

16.0 |

11.0 |

30 |

50 |

| HTC20 |

20 |

17 |

21.2 |

16.1 |

40 |

50 |

| HTC25 |

25 |

22 |

25.3 |

21.0 |

45 |

50 |

| HTC28 |

28 |

23 |

28.5 |

22.5 |

45 |

50 |

Harnessflex has launched its new TempGuard range in response to increased demand from the automotive market for conduit and fittings that work with high temperature cable wiring to ensure performance near engine hot spots.

Modern engine design has continually evolved to meet changing times, usages, and regulations such as emissions, safety, and noise standards, whilst pursuing ever greater efficiency. Changes such as EGR systems that recycle an engine's waste gases and the use of single or multiple turbos to improve tractability, power, and fuel efficiency, have helped to create ‘hot spots' within engines, creating a need for specialist protection of high temperature cable wiring.

Harnessflex's TempGuard conduit and fittings system is designed to work specifically with high temperature cables, allowing them to successfully operate at up to 200°C, with long term heat aging, tensile, and impact strength testing carried out to ensure the reliability and validity of the range. Designed from the outset for use as a full system, it provides a complete solution for the protection and routing of high temperature wiring in and around hot spot areas of the engine.

Lee Callegari, Global Business Development Director at Harnessflex, said: “Global regulations such as Euro 6, USA10, and Tier 4 for off-highway heavy duty vehicles have mandated that manufacturers reduce emission levels. This required reduction, along with changes to engine design to improve safety and reduce noise, have resulted in higher engine temperatures and led to more engine manufacturers using cables that guarantee performance in these environments. We believe our new TempGuard range more than fulfils the need for a complete and effective conduit solution.

“This new product has been created by a specialist team with vast engineering, R&D, and industry experience, backed by the support of leading global in-house manufacturing capabilities and a global supply chain.”

The TempGuard range from Harnessflex increases the temperature rating by more than 60% over standard fittings in the range. With a wide range of fittings and conduits available, made from specialist polyamide and co-polyester materials respectively, the range includes HTC08 - HTC20 conduit, with respective T and Y-Piece fittings, straight and elbow joiners, along with backshells for AMP, Bosch, Deutsch and FCI connectors.

|

![]()

![]()

![]()