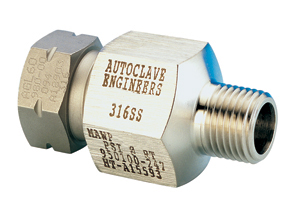

Autoclave Engineers Adapters/Couplings 接头

从1945年开始,Autoclave Engineers开始生产具有安全、可靠操作性的高压阀系统,它们可以适用于各种温度、压力和环境状况。今天,AutoclaveEngineers已经发展成为各类高压行业提供可靠的高压阀、接头和管子的世界领先者。产品性能是Autoclave Engineers对客户的承诺,Autoclave的阀、接头和管子满足严格的标准,它的压力可以从0到150,000 psi(10343 bar) ,温度从 0 到 1200°F (650°C)有上千种变化。没有别的工厂能比Autoclave Engineers在高压要求方面做得更好,也没有别的工厂能比Autoclave Engineers做的系统更可靠和具有创新的特性。Autoclave Engineers的产品为满足客户的各种需求而设计,并且具有品质高,交货准时,价格适当的特点。

AUTOCLAVE产品包括针阀 球阀 安全阀 仪表阀 特制的阀和阀组 气动执行器 接头 热电偶 压力表

Autoclave Engineers Adapters/Couplings 接头:

压力:0.055(1.4 bar)到150,000 psi (10343 bar)

温度:-423°F (-252°C)到1200°F (650°C)

连接尺寸:1/16”到1-5/16”的管外径

材质:316不锈钢

Valves, Fittings, and Tubing Catalog

Autoclave高压接头

Autoclave高压接头-中国总代理的详细描述:

Autoclave高压接头规格参数

最大工作压力:1034.3 MPa

工作温度范围:-423℉(-252℃) 到1200℉(649℃)

连接尺寸:1/16”到1”

材质:316SS

AutoclaveEngineers公司是以生产世界领先的高压阀、接头和管子而著名。压力可以从0到150,000 psi(10342 bar),温度从-423°F(-252°C)到1200°F(649°C)。没有别的工厂能比Autoclave Engineers在高压要求方面做的更好,也没有别的工厂能比AutoclaveEngineers做的系统更可靠、更具有创新的特性。

Autoclave高压阀门:高压针阀、高压球阀、安全阀、仪表阀、特制的阀和阀组、接头、管子、压力表、热电偶、气动执行器。

应用领域:海上油井.石油化工及航天领域.

Autoclave高压接头型号

Male/Female Adapters

15M92R1 6M94R2 6M96R2 4M98R2 15M94R6 15M96R615M99R6 15M94R3 15M96R3 15M99R3

10M92R8 10M94R8 10M96R8 10M98R815M72E1 6M74E2 6M76E2 4M78E2 15M74E6 15M76E6

15M79E6 15M74E315M76E3 15M79E3 10M72E8 10M74E8 10M76E8 10M78E8 15M92E1

6M94E26M96E2 4M98E2 15M94E6 15M96E6 15M99E6 15M912E6 15M94E3 15M96E310M92E8

10M94E8 10M96E8 10M98E8 10M912E8 10M916E8 15M122E1 6M124E26M126E2 4M128E2

15M124E6 15M126E6 15M129E6 15M1212E6 15M1216E615M124E3 15M126E3 15M129E3

10M122E8 10M124E8 10M126E8 10M128E810M1212E8 10M1216E8 43M164B3 43M166B3

43M169B3 43M169B40 15M42B16M44B2 6M46B2 4M48B2 20M44B6 20M46B6 20M49B6 20M412B6

43M416B360M45B3 60M46B3 60M49B3 15M42B8 15M44B8 15M46B8 15M48B8 10M412B86M54B2

6M56B2 4M58B2 20M54B6 20M56B6 20M59B6 20M512B6 60M54B360M56B3 60M59B3 15M58B8

10M512B8 15M62B1 6M64B2 6M66B2 4M68B220M64B6 20M66B6 20M69B6 20M612B6 20M616B6

43M616B6 60M64B3 60M65B360M69B3 15M62B8 15M64B8 15M66B8 15M68B8 10M612B8

10M616B8 15M92B16M94B2 6M96B2 4M98B2 20M94B6 20M96B6 20M99B6 20M912B6

20M916B643M916B3 60M94B3 60M95B3 60M96B3 15M92B8 15M94B8 15M96B8

15M98B810M912B8 10M916B8 20M912G6 15M98G8 15M22N1 15M24N2 15M26N2

10M28N215M24N6 15M26N6 15M29N6 15M24N3 15M26N3 15M29N3 15M42N1 15M44N215M46N2

10M48N2 15M44N6 15M46N6 15M49N6 15M412N6 15M416N6 15M424N615M44N3 15M45N3

15M46N3 15M49N3 15M48N8 15M62N1 15M64N2 15M66N210M68N2 15M64N6 15M66N6 15M69N6

15M612N6 15M616N6 15M64N3 15M66N315M69N3 15M69N40 10M68N8 15M82N1 15M84N2

15M86N2 10M88N2 15M84N615M86N6 15M89N6 15M812N6 15M816N6 15M84N3 15M86N3 15M89N3

15M89N4010M812N8 10M124N2 10M126N2 10M128N2 10M124N6 10M126N6 10M129N610M1212N6

10M1216N6 10M124N3 10M126N3 10M129N3 10M122N8 10M166N210M168N2 10M166N6 10M169N6

10M1612N6 10M1616N6 10M166N3 10M169N310M168N8 6M24C2 6M26C2 4M28C2 6M24C6 6M26C6

6M29C6 6M24C3 6M26C36M29C3 15M22C8 15M24C815M26C8 15M28C8 15M224C6 6M42D1 6M46D2

4M48D26M44D6 6M46D6 6M49D6 6M412D6 6M44D3 6M46D3 6M49D3 15M42D8 15M44D815M46D8

15M48D8 10M412D8 6M62D1 6M64D2 4M68D2 6M64D6 6M66D6 6M69D66M612D6 6M616D6 6M64D3

6M66D3 6M69D3 15M62D8 15M64D8 15M66D815M68D8 10M612D8 10M616D8 15M624D6 4M82D1

4M84D2 4M86D2 4M84D64M86D6 4M89D6 4M812D6 4M816D6 4M84D3 4M86D3 4M89D3 10M82D8

10M84D810M86D8 10M88D8 10M812D8 10M816D8 15MX42K1 6MX44K2 6MX46K2

4MX48K220M46K6 20M49K6 20M412K6 20M416K6 20M44K3 20M45K3 20M46K3

20M49K315MX42K8 15MX44K8 15MX46K8 15MX48K8 10MX412K8 15MX62K1 6MX64K26MX66K2

4MX68K2 20M64K6 20M69K6 20M612K6 20M616K6 20M64K3 20M65K320M66K3 20M69K3

15MX62K8 15MX64K8 15MX66K8 15MX68K8 10MX612K810MX616K8 15MX92K1 6MX94K2 6MX96K2

4MX98K2 20M94K6 20M96K6 20M912K620M916K6 20M94K3 20M95K3 20M96K3 20M99K3

15MX92K8 15MX94K8 15MX96K815MX98K8 10MX912K8 10MX916K8 6MX124K2 6MX126K2

4MX128K2 20M124K620M126K6 20M129K6 20M1216K6 20M124K3 20M125K3 20M126K3

20M129K320M129K40 15MX124K8 15MX126K8 15MX128K8 10MX1212K8 10MX1216K86MX162K2

6MX164K2 6MX166K2 4MX168K2 20M164K6 20M166K6 20M169K620M1612K6 20M164K3 20M166K3

20M169K3 15MX164K8 15MX166K8 15MX168K810MX1612K8 10MX1616K8 15M244K6

Couplings

60F4433 60F4633 60F4933 60F4533 43F4163360F6633 60F6933 60F6533

20FX4466 20F4666 20F4966 20F41266 20F4166620F4463 20F4663 20F4963 20F4563

20F41663 20FX6666 20F6966 20F6126620F61666 20F6463 20F6663 20F6963 20F6563

20F61663 20FX9966 20F9126620F91666 20F9463 20F9663 20F9963 20F9563 20FX12

20F121666 20F1246320F12663 20F12963 20F12563 20FX16 20F16463 20F16663

20F1696320F16563 15F221 6F2412 6F2612 4F2812 15F2416 15F2616 15F291615F21616

15F2413 15F2613 15F2913 6F4422 6F4622 4F4822 6F4426 6F46266F4926 6F4423 6F4623

6F4923 6F6622 4F6822 6F6426 6F6626 6F69266F61226 6F61626 6F6423 6F6623 6F6923

4F8822 4F8426 4F8626 4F89264F81226 4F81626 4F8423 4F8623 4F8923 15F2281 15F2482

15F268210F2882 15F2486 15F2686 15F2986 15F21286 15F2483 15F2683 15F298315F2583

15F4281 15F4482 15F4682 10F4882 15F4486 15F4686 15F498615F41286 15F41686 15F4483

15F4683 15F4983 15F4583 15F6281 15F648215F6682 10F6882 15F6486 15F6686 15F6986

15F61286 15F61686 15F648315F6683 15F6983 15F6583 15F8281 15F8482 15F8682 10F8882

15F848615F8686 15F8986 15F81286 15F81686 15F8483 15F8683 15F8983

15F858310F12882 10F12686 10F12986 10F121286 10F121686 10F12983

10F1698610F161686 10F16483 10F16983

43F61633 60F9933 40F9933 60F9533 43F91633150F5533 43F16 15M249K6 15M2412K6

15M2416K6 60F4433 60F4633 60F493360F4533 43F41633 60F6633 60F6933 60F6533

43F61633 60F9933 40F993360F9533 43F91633 150F5533 43F16 0F4433 60F4633 60F4933

60F453343F41633 60F6633 60F6933 60F6533 43F61633 60F9933 40F9933

60F953343F91633 150F5533 43F16 15MFAP6J6

Male/Male Adapters

15MAL2L2 15MAL2L4 15MAL4L4 10MAL8L810MAL6L8

15MAP4RH9 15MAP4RH12 15MAP4RH16 15MAP6RH915MAP6RH12 15MAP6RH16 15MAP8RH9

15MAP8RH12 15MAP8RH14 15MAP8RH1610MAP12RH12 10MAP12RH16 10MAP16RH16 10MAP12RH21

10MAP16RH2110MAP16RH9 26MARH9RH16 26MARH12RH16 26MARH16RH16

30MARH9RH1230MARH12RH12 40MARH9RH9 20MARH21RH21 26MAH4RH16 26MAH6RH1626MAH9RH16

30MAH4RH12 30MAH6RH12 30MAH9RH12 40MAH4RH9 40MAH6RH940MAH9RH9 20MAM4RH9

20MAM4RH12 20MAM4RH16 20MAM6RH9 20MAM6RH1220MAM6RH16 20MAM9RH9 20MAM9RH12

20MAM9RH14 20MAM9RH16 20MAM12RH920MAM12RH12 20MAM12RH16 20MAM12RH21 20MAM16RH9

20MAM16RH1220MAM16RH14 20MAM16RH16 20MAM16RH21 20MAM9RH21 15MAP4P4

15MAP4P615MAP4P8 15MAP6P6 15MAP6P8 15MAP8P8 15MAP4P4 15MAP4P6 15MAP4P815MAP6P6

15MAP6P8 15MAP8P8 15MAH4P4 15MAH4P6 15MAH4P8 15MAH6P415MAH6P6 15MAH6P8 15MAH9P4

15MAH9P6 15MAH9P8 15MAM4P4 15MAM4P615MAM4P8 15MAM6P4 15MAM6P6 15MAM6P8 15MAM9P4

15MAM9P6 15MAM9P815MAM12P4 15MAM12P6 15MAM12P8 15MAM16P4 15MAM16P6

15MAM16P810MAM9P16 10MAM12P12 10MAM12P16 10MAM16P16 10MAM9P12 15MAL2P215MAL2P4

15MAL4P2 15MAL6P4 10MAL8P6 15MAL2P8 15MAL4P8 15MAL6P810MAL8P12 10MAL8P8 40MAH9H9

60MAH4H4 60MAH4H5 60MAH4H6 60MAH4H960MAH5H6 60MAH6H6 60MAH6H9 60MAH9H9 150MAH5H5

20MAM4M4 20MAM4M620MAM4M9 20MAM4M12 20MAM4M16 20MAM6M6 20MAM6M9 20MAM6M12

20MAM6M1620MAM9M9 20MAM9M12 20MAM9M16 20MAM12M12 20MAM12M16 20MAM16M420MAM4M4

20MAM4M6 20MAM4M9 20MAM4M12 20MAM4M16 20MAM6M6 20MAM6M920MAM6M12 20MAM6M16

20MAM9M9 20MAM9M12 20MAM9M16 20MAM12M1220MAM12M16 20MAM16M4 20MAM16M16 15MAL2H4

10MAL2H6 15MAL4M410MAL8M9

QSS系列高压接头

15MAQ6P415MAQ9H415MAQ4RH9 15MAQ6RH9 15MAQ9RH9 15MAQ9RH12 15MAQ9RH16

15M44NQ15M46NQ 15M64NQ 15M66NQ 15M69NQ 15M84NQ 15M86NQ 15M89NQ 10M129NQ10M1212NQ

10M169NQ 10M1612NQ 15M812NQ 15M44BQ 15M46BQ 15M94BQ15M96BQ 15M99BQ 15M66BQ

15M912BQ 15M64KQ 15M66KQ 15M612KQ 15M94KQ15M96KQ 15M99KQ 15M912KQ 15M1212KQ

15M169KQ 15M1612KQ 15M49KQ15M44KQ 15M46KQ 15M64QQ 15M94QQ 15M96QQ 15M126QQ

15M129QQ 15M49QQ15M612QQ 15M912QQ 15M124QQ 15M44Q8 15M64Q8 15M66Q8 15M68Q8

15M94Q815M96Q8 15M98Q8 15M128Q8 15MFAP6J6

Male/Male JIC Adapters

20MAJ6J6 20MAJ4J4 20MAJ6J8 20MAJ8J8 20MAH4J420MAH4J6 20MAH4J8 20MAH6J4 20MAH6J6

20MAH6J8 20MAH9J4 20MAH9J620MAH9J8 20MAH4J10 20MAH4J2 15MAM4J12 15MAM6J12

15MAM9J1215MAM12J12 15MAM12J16 15MAM16J12 15MAM16J16 20MAM4J4 20MAM4J620MAM4J8

20MAM6J4 20MAM6J6 20MAM6J8 20MAM9J4 20MAM9J6 20MAM9J820MAM9J10 20MAM12J4

20MAM12J6 20MAM12J8 20MAM16J4 20MAM16J620MAM16J8 15MAM4J16 15MAM6J16

15MAM9J1615MAL4J4

15MAP4J4 15MAP4J6 15MAP4J8 15MAP4J12 15MAP6J415MAP6J6 15MAP6J8 15MAP6J12

15MAP8J4 15MAP8J8 15MAP8J12

Male/Female JIC Adapters

20MFAH4J4 20MFAM4J4 20MFAM4J6 20MFAJ12J415MFAJ4P4 15MFAJ4P8 20MFAJ4H4 20MFAJ4H6

20MFAJ4H9 20MFAJ6H620MFAJ4M4 20MFAJ4M6 20MFAJ4M9 20MFAJ4M12 20MFAJ4M16

20MFAJ6M420MFAJ6M6 20MFAJ6M9 20MFAJ6M12 20MFAJ6M16 20MFAJ8M4 20MFAJ8M620MFAJ8M9

20MFAJ8M12 20MFAJ8M16 15MFAJ12M4 15MFAJ12M6 15MFAJ12M915MFAJ12M12 15MFAJ12M16

15MFAJ16M4 15MFAJ16M6 15MFAJ16M915MFAJ16M12 15MFAJ16M16 20MFAJ4M4 20MFAJ4M6

20MFAJ4M9 20MFAJ4M1220MFAJ4M16 20MFAJ6M4 20MFAJ6M6 20MFAJ6M9 20MFAJ6M12

20MFAJ6M1620MFAJ8M4 20MFAJ8M6 20MFAJ8M9 20MFAJ8M12 20MFAJ8M16

15MFAJ12M415MFAJ12M6 15MFAJ12M9 15MFAJ12M12 15MFAJ12M16 15MFAJ16M4

15MFAJ16M615MFAJ16M9 15MFAJ16M12 15MFAJ16M16

Bulkhead系列

20BAMJ4FH420BAMJ6FH4 20BAMJ4FM4 20BAMJ4FM6 20BAMJ6FM4 20BAMJ6FM6

20BAMJ6FM920BAMJ8FM6 20BAMJ8FM9 20BAMJ8FM12 20BAMJ4FM12 20BAMJ6FM1220BAMJ8FM16

15BAMJ4FL4 15BAMP6FM6 15BAMP4FM4 15BAMP4FM640BAMRH9FH4 40BAMRH9FH9 30BAMRH12FH9

20BAMRH9FM6 20BAMRH9FM920BAMRH12FM9 20BAMRH12FM16 20BAMRH16FM16 20BAMRH9FM4

SAE O-Ring Adapters

M44MC2B M46MC2B M44MC3B M46MC3B M64MC3BM66MC3B M24MC6B M26MC6B M44MC6B M46MC6B

M49MC6B M64MC6B M66MC6BM69MC6B M86MC6B M89MC6B M812MC6B M1012MC6B M1016MC6B

M126MC6BM1212MC6B M1216MC6B M1616MC6B

Needle Valves . Low Pressure to 11,500 psi (793 bar) . Medium Pressure to 20,000 psi (1379 bar) . High Pressure to 150,000 psi (10342 bar) . Mini Valves to 15,000 psi (1034 bar) . Micrometering Valves . Block and Bleed Valves . Extreme Temperature Valves . Diverter Valves . Yoke Valves . Valve Options Valve Actuators . Piston . Diaphragm . Solenoid Packages Fittings and Tubing . Low Pressure to 15,000 psi (1034 bar) . Elbows, Tees & Crosses . Straight and Bulkhead Couplings . Tubing . Filter / Check Valves . Medium Pressure to 20,000 psi (1379 bar) . Elbows, Tees & Crosses . Straight, Union and Bulkhead Couplings . Tubing & Nipples . Filter / Check Valves . Anti-Vibration Collet and Gland Assembly . High Pressure to 150,000 psi (10342 bar) . Elbows, Tees & Crosses . Straight, Union and Bulkhead Couplings . Tubing & Nipples . Filter / Check Valves . Anti-Vibration Collet and Gland Assembly Adapters / Couplings . Couplings . Male / Female . Male/Male . Male/Male JIC/BSP . EZ-Union . Header Couplings . Bulkhead . Tube Caps & Gauge Connectors Ball Valves . 2-Way . 3-Way . 4-Way . Subsea . Actuators . Options/Details Relief Valves . Metal Seat . Soft Seat Custom Valves & Manifold . Special Connection Valves . NPT Valves . Bottle Valves . Custom Valves and Special Materials . Manifold Blocks . Clamp Style Manifolds Accessories . Thermocouples . Safety Heads / Rupture Discs . Gauges Sour Service Products . General information . Well Head Gauge and Bleed Valves . Stem Valves . Fittings and Tubing . Check Valves and Adapters . Servere Service Valves . Gauges Metric Series . Valves . Valves Actuators . Fittings . Tubing and Nipples . Safety Head Assembly and Rupture Discs . Manual Coning & Threading Tools . Gauges Instrumentation Valves

.

5000 Series Needle / Gauge Valves

.

5000 Series Manifold Valves

Tools, Installation, Operation & Maintenance . Low Pressure Connection Installation . Manual Coning and Threading Tools . Medium and High Pressure Connection Installation . Anti-Vibration Collet Gland Assembly . Reseating Female Cone Seats . AEGCTM Coning and Threading Machine . Torque Wrench and Torque Adapters . Torque Values . Tube Connection Dimensions . Hydraulic Tube Bender . Lubrication Guide Technical Information . Technical and Application Information . Autofrettage and High Cycle Tubing . Medium & High-Pressure Connections . Pressure/Temperature Rating Guide . Material vs. Rating Curves . Flow Calculations and Liquid Flow Curves . Conversion Tables . Pressure vs. Bend Radius

ISO-9001

Certified

02-0100CE-0302

www.autoclaveengineers.com

Needle Valve

Index

Low Pressure Valves:

. 10V & SW Series, Pressures to 11,500 psi. (793 bar)

Medium Pressure Valves:

. SM Series, Pressures to 20,000 psi. (1379 bar)

(Note: SM Series replace existing SC Series)

High Pressure Valves:

. 30SC, 30VM, 40VM, 60VM, 100V, & 150V Series, Pressures to 150,000 psi. (10342 bar)

Mini Valves:

. MVE Series, Pressures to 15,000 psi. (1034 bar)

Micro Metering Valves: . VRMM Series, Pressures to 60,000 psi. (4137 bar) Block and Bleed Valves: . 20MVBB, Rated to 20,000 psi. (1379 bar) Extreme Temperture Valves: . HT, LT, & PV Series, Pressures to 60,000 psi. (4137 bar) Diverter Valves:

. 20DV Series, Pressures to 20,000 psi. (1379 bar)

Yoke Valves:

. 15Y, 43Y & 50Y Series, Pressures to 50,000 psi. (3447 bar)

Valve Options:

. Stem Types, Material Selection, Coatings and Handles

ISO-9001

Certified

Needle Valves

Low Pressure

10V & SW Series

Pressures to 11,500 psi (793 bar)

Since 1945 Autoclave Engineers has designed and built premium quality valves, fittings and tubing. This commitment to engineering and manufacturing excellence has earned Autoclave a reputation for reliable efficient product performance. Autoclave Engineers has long been established as the world leader in high pressure fluid handling components for the chemical/petrochemical, research, and oil and gas industries.

Low Pressure Valve Features:

.

10V Series valve design provides in-line tube connections for 1/4” to 1/2” tube sizes.

.

SW Series valve design provides increased flow capabilities.

.

Tubing sizes from 1/16” to 1/2”.

.

Rising stem/barstock body design.

.

Non-rotating stem prevents stem/seat galling.

.

Metal-to-metal seating achieves bubble-tight shutoff, longer stem/seat life in abrasive flow, greater durability for repeated on/off cycles and excellent corrosion resistance.

.

PTFE (Teflon) encapsulated packing provides dependable stem and body sealing.

.

Stem sleeve and packing gland materials have been selected to achieve extended thread cycle life and reduced handle torque.

.

Choice of Vee or Regulating stem tips.

.

Available in five body patterns.

Autoclave valves are complemented by a complete line of low pressure fittings, tubing, check valves and line filters. The 10V and SW series use Autoclave’s SpeedBite connection. This single-ferrule compression sleeve connection delivers fast, easy make-up and reliable bubble-tight performance in liquid or gas service.

www.autoclaveengineers.com

Valve Series -10V Series

Pressures to 11,500 psi (793 bar)

All general terms and conditions of sale, including limitations of our liability, apply to all products and services sold.

Number of turns open

For complete information on available stem types, optional connections and additional valve options, see Needle Valve Options section or contact your Sales Representative. 10V Series valves are furnished complete with connection components, unless otherwise specified.

Vee stem (on-off service)

regulating stem (tapered tip for regulating and shutoff)

Tube Pres./Temp. Outside Rating Diameter Orifice psi (bar) Size Connection Size Rated @ Room Inches Type Inches (mm) Cv*Temperature**

1/8 W125 0.094 (2.39) 0.12 11,000 (758) 1/4 W250 0.125 (3.18) 0.20 11,500 (793) 3/8 W375 0.125 (3.18) 0.20 10,000 (690) 1/2 SW500 0.250 (6.35) 0.86 5,500 (379)

Notes: *CV values shown are for 2-way straight valve pattern. For 2-way angle patterns, increase CV value 50%. (Based on water) ** For complete temperature ratings see pressure/temperature rating guide in Technical Information section.

Generalized Flow Coefficient Curves (Cv)

7 6 5 4 3 2 1 0

% of rated Cv

To ensure proper fit use Autoclave tubing

Ordering Procedure

Typical catalog number: 10V4071 4 07

10V

1

Options

Valve Outside Diameter Stem/Seat Body Options Series Tube Size Type

Pattern

For extreme

1 -two-way straight

2-1/8” 07 -non-rotating temperature and other

4-1/4”

2 -two-way angle options, see Valve 6-3/8” 08 -non-rotating 3 -three-way, two on pressure Options.

8-1/2”

4 -three-way, one on pressure

5 -three-way, two stem

manifold valve

87 -Vee stem with replaceable Note: Contact Sales for 1/16”tube size or seat see MVE Series.

88 -Regulating stem with replaceable seat

Valve Options

Extreme Temperatures

Standard Autoclave valves with Teflon packing may be operated to 450°F (232°C). High temperature packing and/or extended stuffing box is available for service from 0°F (-17.8°C) to 650°F (343°C) by adding the following suffixes to catalog order number..TG standard valve with Teflon glass packing to 600°F (316°C). GY standard valve with graphite braided yarn packing to 650°F (343°C).

.Autoclave Engineers does not recommend compression sleeve connections below 0 ° F (-17.8 ° C) or above 650 ° F (343 ° C). For additional valve options, contact your Sales Representative.

Valve Maintenance

Repair Kits: add “R” to the front of valve catalog number for proper repair kit. (Example: R10V4071)

Valve Bodies: Valve bodies are available. Order using the eight (8) digit part number found on the valve drawing or contact your Sales Representative for information.

Consult your Autoclave representative for pricing on repair kits and valve bodies. Refer to the Tools, Installation, Operation and Maintenance section for proper maintenance procedures.

2-Way Straight

10V2071 VEE 1/8** 0.094 1.50 0.75 0.31 1.06 0.81 1.38 3.00 0.62 0.17 3.75 0.56 0.31 0.62 See Figure 1

10V2081 REG (3.18) (2.39) (38.10) (19.05) (7.87) (26.92) (20.57) (35.05) (76.20) (15.75) (4.32) (95.25) (14.22) (7.87) (15.75)

10V4071 VEE 1/4 0.125 2.00 1.00 0.56 1.19 1.69 3.00 0.97 0.22 4.44 0.69 0.38 1.00

10V4081 REG (6.35) (3.18) (50.80) (25.40) (14.22) (30.23) (42.93) (76.20) (24.64) (5.59) (112.78) (17.53) (9.65) (25.40)

10V6071 VEE 3/8 0.125 2.00 1.00 0.62 1.19 1.69 3.00 0.97 0.22 4.31 0.69 0.38 1.00

10V6081 REG (9.53) (3.18) (50.80) (25.40) (15.75) (30.23) (42.93) (76.20) (24.64) (5.59) (109.47) (17.53) (9.65) (25.40)

10V8071 VEE 1/2 0.250 2.50 1.25 0.53 1.25 1.81 3.00 0.97 0.22 4.44 0.69 0.38 1.00

10V8081 REG (12.70) (6.35) (63.50) (31.75) (13.46) (31.75) (45.97) (76.20) (24.64) (5.59) (112.78) (17.53) (9.65) (25.40)

2-Way Angle

10V2072 VEE 1/8 0.094 1.50 0.75 0.31 0.81 1.56 3.00 0.62 0.17 3.94 0.50 0.31 0.62 See Figure 2

10V2082 REG (3.18) (2.39) (38.1) (19.05) (7.87) (20.57) (39.62) (76.20) (15.75) (4.32) (100.08) (12.70) (7.87) (15.75)

10V4072 VEE 1/4 0.125 2.00 1.00 0.56 1.19 2.19 3.00 0.97 0.22 4.81 0.69 0.31 1.00

10V4082 REG (6.35) (3.18) (50.80) (25.40) (14.2) (30.23) (55.63) (76.20) (24.64) (5.59) (122.17) (17.53) (7.87) (25.40)

10V6072 VEE 3/8 0.125 2.00 1.00 0.62 1.19 2.19 3.00 0.97 0.22 4.81 0.69 0.31 1.00

10V6082 REG (9.53) (3.18) (50.80) (25.40) (15.7) (30.23) (55.63) (76.20) (24.64) (5.59) (122.17) (17.53) (7.87) (25.40)

10V8072 VEE 1/2 0.250 2.50 1.25 0.53 1.25 2.50 3.00 0.97 0.22 5.06 0.69 0.38 1.00

10V8082 REG (12.70) (6.35) (63.50) (31.75) (13.5) (31.75) (63.50) (76.20) (24.64) (5.59) (128.52) (17.53) (9.65) (25.40)

3-Way / 2 on Pressure

10V2073 VEE 1/8** 0.094 1.50 0.75 0.31 1.06 0.81 1.69 3.00 0.62 0.17 4.06 0.50 0.31 0.62 See Figure 3

10V2083 REG (3.18) (2.39) (38.10) (19.05) (7.87) (26.92) 20.57 (42.93) (76.20) (15.75) (4.32) (103.12) (12.70) (7.87) (15.75)

10V4073 VEE 1/4 0.125 2.00 1.00 0.56 1.19 2.19 3.00 0.97 0.22 4.81 0.69 0.38 1.00

10V4083 REG (6.35) (3.18) (50.80) (25.40) (14.22) (30.23) (55.63) (76.20) (24.64) (5.59) (122.17) (17.53) (9.65) (25.40)

10V6073 VEE 3/8 0.125 2.00 1.00 0.62 1.19 2.19 3.00 0.97 0.22 4.81 0.69 0.38 1.00

10V6083 REG (9.53) (3.18) (50.80) (25.40) (15.75) (30.23) (55.63) (76.20) (24.64) (5.59) (122.17) (17.53) (9.65) (25.40)

10V8073 VEE 1/2 0.250 2.50 1.25 0.53 1.19 2.44 3.00 0.97 0.22 5.06 0.69 0.38 1.00

10V8083 REG (12.70) (6.35) (63.50) (31.75) (13.46) (30.23) (61.98) (76.20) (24.64) (5.59) (128.52) (17.53) (9.65) (25.40)

G - Packing gland mounting hole drill size * H Dimension is with stem in closed position. For prompt service, Autoclave stocks

G1 - Bracket mounting hole size ** 1/8” straight and 3-Way/2 on pressure valves have offset select products. Consult factory.

Panel mounting drill size: 0.22” all valves. tube connections. All dimensions for reference only and subject to change.

3-Way / 1 on Pressure

10V2074 VEE 1/8 0.094 1.50 0.75 0.31 0.81 1.56 3.00 0.62 0.17 3.94 0.50 0.31 0.62 See Figure 4

10V2084 REG (3.18) (2.39) (38.1) (19.05) (7.87) (20.57) (39.62) (76.20) (15.75) (4.32) (100.08) (12.70) (7.87) (15.7)

10V4074 VEE 1/4 0.125 2.00 1.00 0.56 1.19 2.19 3.00 0.97 0.22 4.81 0.69 0.38 1.00

10V4084 REG (6.35) (3.18) (50.8) (25.40) (14.22) (30.23) (55.63) (76.20) (24.64) (5.59) (122.17) (17.53) (9.65) (25.40)

10V6074 VEE 3/8 0.125 2.00 1.00 0.62 1.19 2.19 3.00 0.97 0.22 4.81 0.69 0.38 1.00

10V6084 REG (9.53) (3.18) (50.8) (25.40) (15.75) (30.23) (55.63) (76.20) (24.64) (5.59) (122.17) (17.53) (9.65) (25.40)

10V8074 VEE 1/2 0.250 2.50 1.25 0.53 1.19 2.44 3.00 0.97 0.22 5.06 0.69 0.38 1.00

10V8084 REG (12.70) (6.35) (63.5) (31.75) (13.46) (30.23) (61.98) (76.20) (24.64) (5.59) (128.52) (17.53) (9.65) (25.40)

2-Way Angle / Replaceable Seat

10V2872 VEE 1/8 0.094 1.50 0.75 0.31 0.81 1.28 1.56 3.00 0.62 0.17 4.50 0.50 0.31 0.62 See Figure 5

10V2882 REG (3.18) (2.39) (38.10) (19.05) (7.87) (20.57) (32.51) (39.62) (76.20) (15.75) (4.32) (114.30) (12.70) (7.87) (15.75)

10V4872 VEE 1/4 0.125 2.00 1.00 0.56 1.12 2.13 2.25 3.00 0.97 0.22 6.00 0.69 0.38 1.00

10V4882 REG (6.35) (3.18) (50.80) (25.40) (14.22) (28.45) (54.10) (57.15) (76.20) (24.64) (5.59) (152.40) (17.53) (9.65) (25.40)

10V6872 VEE 3/8 0.125 2.00 1.00 0.62 1.12 2.28 2.25 3.00 0.97 0.22 6.00 0.69 0.38 1.00

10V6882 REG (9.53) (3.18) (50.80) (25.40) (15.75) (28.45) (57.91) (57.15) (76.20) (24.64) (5.59) (152.40) (17.53) (9.65) (25.40)

10V8872 VEE 1/2 0.250 2.50 1.25 0.53 1.00 2.50 2.38 3.00 0.97 0.28 6.06 0.69 0.38 1.00

10V8882 REG (12.70) (6.35) (63.50) (31.75) (13.46) (25.45) (63.50) (60.45) (76.20) (24.64) (7.11) (153.92) (17.53) (9.65) (25.40)

3-Way / 2-Stem Manifold

10V2075 VEE 1/8 0.094 1.50 0.75 0.31 1.12 0.81 2.25 3.00 0.62 0.17 4.63 0.50 0.31 0.62 See Figure 6

10V2085 REG (3.18) (2.39) (38.10) (19.05) (7.87) (28.45) (20.57) (57.15) (76.20) (15.75) (4.32) (117.60) (12.70) (7.87) (15.7)

10V4075 VEE 1/4 0.125 2.00 1.00 0.56 1.69 1.09 3.38 3.00 0.97 0.22 5.82 0.69 0.38 1.00

10V4085 REG (6.35) (3.18) (50.80) (25.40) (14.22) (42.93) (27.69) (85.85) (76.20) (24.64) (5.59) (147.83) (17.53) (9.65) (25.40)

10V6075 VEE 3/8 0.125 2.00 1.00 0.62 1.69 1.09 3.38 3.00 0.97 0.22 5.82 0.69 0.38 1.00

10V6085 REG (9.53) (3.18) (50.80) (25.40) (15.75) (42.93) (27.69) (85.85) (76.20) (24.64) (5.59) (147.83) (17.53) (9.65) (25.40)

10V8075 VEE 1/2 0.250 2.50 1.25 0.53 1.69 1.03 3.38 3.00 0.97 0.22 5.82 0.69 0.38 1.00

10V8085 REG (12.70) (6.35) (63.50) (31.75) (13.46) (42.93) (26.16) (85.85) (76.20) (24.64) (5.59) (147.83) (17.53) (9.65) (25.40)

G - Packing gland mounting hole drill size * H Dimension is with stem in closed position. For prompt service, Autoclave

G1 - Bracket mounting hole size All dimensions for reference only and subject to change. stocks select products.

Panel mounting drill size: 0.22” all valves. Consult factory.

Needle Valves -SW Series

Pressures to 11,500 psi (793 bar)

All general terms and conditions of sale, including limitations of our liability, apply to all products and services sold.

Number of turns open

For complete information on available stem types, optional connections and additional valve options, see Needle Valve Options section or contact your Sales Representative. SW Series valves are furnished complete with connection components, unless otherwise specified.

Vee stem (on off service)

regulating stem (tapered tip for regulating and shutoff) 87 -Vee stem with replaceable

Pressure/ Tube Temperature Outside Rating Diameter Orifice psi (bar) Size Connection Size Rated @ Room Inches Type Inches (mm) Cv*Temperature**

1/8 W125— Refer to 10V Series Valves — 1/4 SW250 0.188 (4.77) 0.65 11,500 (793) 3/8 SW375 0.250 (6.35) 0.95 10,000 (690) 1/2 SW500 0.375 (9.52) 1.90 5,500 (379)

Notes: *CV values shown are for 2-way straight valve pattern. For 2-way angle patterns, increase CV value 50%. (Based on water) ** For complete temperature ratings see pressure/temperature rating guide in Technical Information section.

Generalized Flow Coefficient Curves (Cv)

7 6 5 4 3 2 1 0

% of rated Cv

To ensure proper fit use Autoclave tubing

Ordering Procedure

Typical catalog number: SW4071

SW4 07

1 Options

Valve Outside Diameter Stem/Seat Body Options

Series Tube Size Type Pattern

For extreme

1 -two-way straight

4-1/4” 07 -non-rotating temperature and other

6-3/8”

2 -two-way angle options, see Valve 8-1/2” 08 -non-rotating 3 -three-way, two on pressure Options.

4 -three-way, one on pressure

5 -three-way, two stem

manifold valve

seat

88 -Regulating stem with replaceable seat

Valve Options

Valve Maintenance

Extreme Temperatures

Standard Autoclave valves with Teflon packing may be operated to 450°F (232°C). High temperature packing and/or extended stuffing box are available for service from 0°F (-17.8°C) to 650°F (343°C) by adding the following suffixes to catalog order number..TG standard valve with Teflon glass packing to 600°F (316°C). GY standard valve with graphite braided yarn packing to 650°F (343°C).

.Autoclave Engineers does not recommend compression sleeve connections below 0 ° F (-17.8 ° C) or above 650 ° F (343 ° C). For additional valve options, contact your Sales Representative.

Repair Kits: add “R” to the front of valve catalog

number for proper repair kit.

(Example: RSW4071)

Valve Bodies: Valve bodies are available. Order using the eight (8)

digit part number found on the valve drawing or

contact your Sales Representative for information.

Consult your Autoclave representative for pricing on repair kits and valve bodies. Refer to the Tools, Installation, Operation and Maintenance section for proper maintenance procedures.

2-Way Straight

SW4071 VEE 1/4 0.187 2.00 1.00 0.38 1.62 1.19 2.00 3.00 0.75 0.22 4.50 0.62 0.38 0.75 See Figure 1

SW4081 REG (6.35) (4.75) (50.80) (25.40) (9.65) (41.15) (30.23) (50.80) (76.20) (19.05) (5.59) (114.30) (15.75) (9.65) (19.05)

SW6071 VEE 3/8 0.250 2.00 1.00 0.47 1.62 1.19 2.00 3.00 0.75 0.22 4.50 0.62 0.38 0.75

SW6081 REG (9.53) (6.35) (50.80) (25.40) (11.94) (41.15) (30.23) (50.80) (76.20) (19.05) (5.59) (114.30) (15.75) (9.65) (19.05)

SW8071 VEE 1/2 0.375 2.50 1.25 0.53 2.38 1.75 2.88 4.00 1.00 0.34 5.95 0.69 0.50 1.00

SW8081 REG (12.70) (9.53) (63.50) (31.75) (13.46) (60.45) (44.45) (73.15) (101.60) (25.40) (8.64) (151.37) (17.53) (12.70) (25.40)

2-Way Angle

SW4072 VEE 1/4 0.187 2.00 1.00 0.38 1.19 2.43 3.00 0.75 0.22 5.00 0.62 0.38 0.75 See Figure 2

SW4082 REG (6.35) (4.75) (50.80) (25.40) (9.65) (30.23) (61.72) (76.20) (19.05) (5.59) (127.00) (15.75) (9.65) (19.05)

SW6072 VEE 3/8 0.250 2.00 1.00 0.47 1.19 2.19 3.00 0.75 0.22 5.00 0.62 0.38 0.75

SW6082 REG (9.53) (6.35) (50.80) (25.40) (11.94) (30.23) (55.63) (76.20) (19.05) (5.59) (127.00) (15.75) (9.65) (19.05)

SW8072 VEE 1/2 0.375 2.50 1.25 0.53 1.75 3.38 4.00 1.00 0.34 6.45 0.69 0.50 1.00

SW8082 REG (12.70) (9.53) (63.50) (31.75) (13.46) (44.45) (85.85) (101.60) (25.40) (8.64) (163.83) (17.53) (12.70) (25.40)

3-Way / 2 on Pressure

SW4073 VEE 1/4 0.187 2.00 1.00 0.38 1.62 1.19 2.62 3.00 0.75 0.22 5.18 0.62 0.38 0.75 See Figure 3

SW4083 REG (6.35) (4.75) (50.80) (25.40) (9.65) (41.15) (30.23) (66.55) (76.20) (19.05) (5.59) (131.57) (15.75) (9.65) (19.05)

SW6073 VEE 3/8 0.250 2.00 1.00 0.47 1.62 1.19 2.62 3.00 0.75 0.22 5.13 0.62 0.38 0.75

SW6083 REG (9.53) (6.35) (50.80) (25.40) (11.94) (41.15) (30.23) (66.55) (76.20) (19.05) (5.59) (130.30) (15.75) (9.65) (19.05)

SW8073 VEE 1/2 0.375 2.50 1.25 0.53 2.38 1.75 3.62 4.00 1.00 0.34 6.70 0.69 0.50 1.00

SW8083 REG (12.70) (9.53) (63.50) (31.75) (13.46) (60.45) (44.45) (91.95) (101.60) (25.40) (8.64) (170.18) (17.53) (12.70) (25.40)

G - Packing gland mounting hole drill size * H Dimension is with stem in closed position. For prompt service, Autoclave stocks

G1 - Bracket mounting hole size All dimensions for reference only and subject to change. select products. Consult factory.

Panel mounting drill size: 0.22” all valves.

3-Way / 1 on Pressure

SW4074 VEE 1/4 0.187 2.00 1.00 0.38 1.19 2.43 3.00 0.75 0.22 5.00 0.62 0.38 0.75 See Figure 4

SW4084 REG (6.35) (4.75) (50.80) (25.40) (9.65) (30.23) (61.72) (76.20) (19.05) (5.59) (127.00) (15.75) (9.65) (19.05)

SW6074 VEE 3/8 0.250 2.00 1.00 0.47 1.19 2.43 3.00 0.75 0.22 5.00 0.62 0.38 0.75

SW6084 REG (9.53) (6.35) (50.80) (25.40) (11.94) (30.23) (61.72) (76.20) (19.05) (5.59) (127.00) (15.75) (9.65) (19.05)

SW8074 VEE 1/2 0.375 2.50 1.25 0.53 1.75 3.38 4.00 1.00 0.34 6.45 0.69 0.50 1.00

SW8084 REG (12.70) (9.53) (63.50) (31.75) (13.46) (44.45) (85.85) (101.60) (25.40) (8.64) (163.83) (17.53) (12.70) (25.40)

2-Way Angle / Replaceable Seat

SW4872 VEE 1/4 0.187 2.00 1.00 0.38 1.19 1.88 2.25 3.00 0.75 0.22 5.75 0.62 0.38 0.75 See Figure 5

SW4882 REG (6.35) (4.75) (50.80) (25.40) (9.65) (30.23) (47.75) (57.15) (76.20) (19.05) (5.59) (146.05) (15.75) (9.65) (19.05)

SW6872 VEE 3/8 0.250 2.00 1.00 0.47 1.19 2.19 2.25 3.00 0.75 0.22 5.75 0.62 0.38 0.75

SW6882 REG (9.53) (6.35) (50.80) (25.40) (11.94) (30.23) (55.62) (57.15) (76.20) (19.05) (5.59) (146.05) (15.75) (9.65) (19.05)

SW8872 VEE 1/2 0.375 2.50 1.25 0.53 1.75 2.50 3.25 4.00 1.00 0.34 7.51 0.69 0.50 1.00

SW8882 REG (12.70) (9.53) (63.50) (31.75) (13.46) (44.45) (63.50) (82.55) (101.60) (25.40) (8.64) (190.75) (17.53) (12.70) (25.40)

3-Way / 2-Stem Manifold

SW4075 VEE 1/4 0.187 2.00 1.00 0.38 1.68 1.19 3.38 3.00 0.75 0.22 5.94 0.62 0.38 0.75 See Figure 6

SW4085 REG (6.35) (4.75) (50.80) (25.40) (9.65) (42.67) (30.23) (85.85) (76.20) (19.05) (5.59) (150.88) (15.75) (9.65) (19.05)

SW6075 VEE 3/8 0.250 2.00 1.00 0.47 1.68 1.19 3.38 3.00 0.75 0.22 5.94 0.62 0.38 0.75

SW6085 REG (9.53) (6.35) (50.80) (25.40) (11.94) (42.67) (30.23) (85.85) (76.20) (19.05) (5.59) (150.88) (15.75) (9.65) (19.05)

SW8075 VEE 1/2 0.375 2.50 1.25 0.53 2.56 1.75 5.12 4.00 1.00 0.34 8.20 0.69 0.50 1.00

SW8085 REG (12.70) (9.53) (63.50) (31.75) (13.46) (65.02) (44.45) (130.05) (101.60) (25.40) (8.64) (208.28) (17.53) (12.70) (25.40)

G - Packing gland mounting hole drill size * H Dimension is with stem in closed position. For prompt service, Autoclave

G1 - Bracket mounting hole size All dimensions for reference only and subject to change. stocks select products. Consult

Panel mounting drill size: 0.22” all valves. factory.

All general terms and conditions of sale, including limitations of our liability, apply to all products and services sold.

Needle Valves

Medium Pressure

SM Series

Pressures to 20,000 psi (1379 bar)

Since 1945 Autoclave Engineers has designed and built premium quality valves, fittings and tubing. This commitment to engineering and manufacturing excellence has earned Autoclave a reputation for reliable efficient product performance. Autoclave Engineers has long been established as the world leader in high pressure fluid handling components for the chemical/petrochemical, waterblast, research, and oil and gas industries.

Medium Pressure Valve Features:

.

Largest-port valves available for medium pressure

applications.

.

Tubing sizes available from 1/4” to 1”.

.

Rising stem/barstock body design.

.

Non-rotating stem prevents stem/seat galling.

.

New one piece stem design permits ease of assembly and packing replacement.

.

Metal-to-metal seating achieves bubble-tight shut-off, longer stem/seat life in abrasive

flow, greater durability for repeated on/off cycles and excellent corrosion resistance.

.

PTFE (Teflon) encapsulated packing provides dependable stem and body sealing.

.

Stem sleeve and packing gland materials have been selected to achieve extended thread cycle life and reduced handle torque.

.

Choice of Vee or Regulating stem tip.

.

Available in five body patterns.

Autoclave valves are complemented by a complete line of fittings, tubing, check valves and line filters. The SM Series uses Autoclave’s Medium pressure connection. The coned-and-threaded connection features orifice sizes to match the high flow characteristics of this series.

Note: SM Series replaces 20SC Series.

www.autoclaveengineers.com

Needle Valves -SM Series

Pressures to 20,000 psi (1379 bar)

For complete information on available stem types, optional connections and additional valve options, see Needle Valve Options section or contact your Sales Representative. 10SM and 20SM Series valves are furnished complete with connection components, unless otherwise

ns openNumber of tur

87 -Vee stem with replaceable seat 88 -Regulating stem with replaceable seat All general terms and conditions of sale, including limitations of our liability, apply to all products and services sold.

Pressure/ Tube Temperature Outside Rating Diameter Orifice psi (bar) Size Connection Size Rated @ Room Inches Type Inches (mm) Cv*Temperature**

1/4 SF250CX20 0.125 (3.18) 0.31 20,000 (1379) 3/8 SF375CX20 0.219 (5.56) 0.75 20,000 (1379) 9/16 SF562CX20 0.312 (7.92) 1.75 20,000 (1379) 3/4 SF750CX20 0.438 (11.13) 2.80 20,000 (1379) 1 SF1000CX20 0.562 (14.27) 5.20 20,000 (1379) 9/16 SF562CX10 0.359 (9.12) 1.75 10,000 (690) 3/4 SF750CX10 0.516 (13.10) 2.80 10,000 (690) 1 SF1000CX10 0.688 (17.48) 5.20 10,000 (690)

Notes: *CV values shown are for 2-way straight valve pattern. For 2-way angle patterns, increase CV value 50%. (Based on water) ** For complete temperature ratings see pressure/temperature rating guide in Technical Information section.

Generalized Flow Coefficient Curves (Cv)

7

0

To ensure proper fit use Autoclave tubing

Ordering Procedure

specified.

Typical catalog number: 20SM4071

20SM 4

07

1

Options

Valve Outside Diameter

Stem/Seat Body Options

Series Tube Size

Type Pattern

For extreme07 -non-rotating 1 -two-way straight

4-1/4”

10SM 6-3/8” Vee stem (on-off service) 2 -two-way angle temperature and other

20SM 9-9/16” 08 -non-rotating

12-3/4” regulating stem (tapered tip

16-1” for regulating and shutoff) options, see Valve

3 -three-way, two on pressure Options.

4 -three-way, one on pressure

5 -three-way, two stem

manifold valve

Valve Options

Valve Maintenance

Extreme Temperatures

Standard Autoclave valves with Teflon packing may be operated to

450°F (232°C). High temperature packing and/or extended stuffing

box are available for service from -423°F (-252°C) to 1200°F

(649°C) by adding the following suffixes to catalog order number.

TG standard valve with Teflon glass packing to 600°F (316°C).

GY standard valve with graphite braided yarn packing to 800°F (427°C).

Note: 3/4” rated 8000 psi (552 bar) and 1” rated 6000 psi (412 bar)

maximum with graphite yarn packing..

HT extended stuffing box valve with graphite braided yarn packing

to 1200°F (649°C).

B standard valve with cryogenic trim materials and Teflon packing

to -100°F (-73°C).

LT extended stuffing box valve with Teflon packing and cryogenic

trim materials to -423°F (-252°C).

.This packing will affect the pressure rating. Refer to Technical Information

section.

See needle valve options for stem and seat coating for erosive service.

2-Way Straight

Repair Kits: add “R” to the front of valve catalog number for proper repair kit. (Example: R20SM4071)

Valve Bodies: Valve bodies are available. Order using the eight (8) digit part number found on the valve drawing or contact your Sales Representative for information.

Consult your Autoclave representative for pricing on repair kits and valve bodies. Refer to the Tools, Installation, Operation and Maintenance section for proper maintenance procedures.

Note: Caution should be exercised in proper selection of medium pressure tubing based on actual operating conditions. Two tubing series available in some sizes: 10,000 psi (690 bar) and 20,000 psi (1380 bar).

20SM4071 VEE 1/4 0.125 2.00 1.00 0.38 1.19 1.62 2.00 3.00 0.75 0.22 4.69 0.62 0.38 0.75 See Figure 1

20SM4081 REG (6.35) (3.18) (50.80) (25.40) (9.65) (30.23) (41.15) (50.80) (76.20) (19.05) (5.59) (119.13) (15.75) (9.65) (19.05)

20SM6071 VEE 3/8 0.219 2.00 1.00 0.47 1.62 1.19 2.00 3.00 0.75 0.22 4.63 0.62 0.38 0.75

20SM6081 REG (9.53) (5.56) (50.80) (25.40) (11.94) (41.15) (30.23) (50.80) (76.20) (19.05) (5.59) (117.48) (15.75) (9.65) (19.05)

20SM9071 VEE 9/16 0.312 2.50 1.25 0.53 2.38 1.75 2.88 4.00 1.00 0.34 5.93 0.69 0.50 1.00

20SM9081 REG (14.29) (7.92) (63.50) (31.75) (13.46) (60.45) (44.45) (73.15) (101.60) (25.40) (8.64) (150.86) (17.53) (12.70) (25.40)

20SM12071 VEE 3/4 0.438 3.00 1.50 0.62 3.00 2.25 3.00 10.25 1.12 0.44 7.00 0.88 0.63 1.38

20SM12081 REG (19.05) (11.13) (76.20) (38.10) (15.75) (76.20) (57.15) (76.20) (260.35) (28.45) (11.18) (177.80) (22.35) (16.00) (35.05)

20SM16071 VEE 1 0.562 4.12 2.06 0.63 3.75 2.81 4.63 10.25 1.62 0.56 9.00 1.25 1.13 1.75

20SM16081 REG (25.40) (14.27) (104.65) (52.32) (16.00) (95.25) (71.37) (117.60) (260.35) (41.15) (14.22) (228.84) (31.75) (28.70) (44.4 5)

10SM9071 VEE 9/16 0.359 2.50 1.25 0.53 2.38 1.75 2.88 4.00 1.00 0.34 5.93 0.69 0.50 1.00

10SM9081 REG (14.29) (9.12) (63.50) (31.75) (13.46) (60.45) (44.45) (73.15) (101.60) (25.40) (8.64) (150.86) (17.53) (12.70) (25.40)

10SM12071 VEE 3/4 0.516 3.00 1.50 0.62 3.00 2.25 3.00 10.25 1.12 0.44 7.00 0.88 0.63 1.38

10SM12081 REG (19.05) (13.11) (76.20) (38.10) (15.75) (76.20) (57.15) (76.20) (260.35) (28.45) (11.18) (177.80) (22.35) (16.00) (35.05)

10SM16071 VEE 1 0.688 4.12 2.06 0.63 3.75 2.81 4.63 10.25 1.62 0.56 9.00 1.25 1.13 1.75

10SM16081 REG (25.40) (17.48) (104.65) (52.32) (16.00) (95.25) (71.37) (117.60) (260.35) (41.15) (14.22) (228.84) (31.75) (28.70) (44.45)

G - Packing gland mounting hole drill size * H Dimension is with stem in closed position. For prompt service, Autoclave

G1 - Bracket mounting hole size All dimensions for reference only and subject to change. stock select products.

Panel mounting drill size: 0.22” all valves. Consult factory.

2-Way Angle

20SM4072 VEE 1/4 0.125 2.00 1.00 0.38 1.19 2.44 3.00 0.75 0.22 4.81 0.62 0.38 0.75 See Figure 2

20SM4082 REG (6.35) (3.18) (50.80) (25.40) (9.65) (30.23) (61.90) (76.20) (19.05) (5.59) (122.25) (15.75) (9.65) (19.05)

20SM6072 VEE 3/8 0.219 2.00 1.00 0.47 1.19 2.44 3.00 0.75 0.22 4.81 0.62 0.38 0.75

20SM6082 REG (9.53) (5.56) (50.80) (25.40) (11.94) (30.23) (61.90) (76.20) (19.05) (5.59) (122.25) (15.75) (9.65) (19.05)

20SM9072 VEE 9/16 0.312 2.50 1.25 0.53 1.75 3.38 4.00 1.00 0.34 6.43 0.69 0.50 1.00

20SM9082 REG (14.29) (7.92) (63.50) (31.75) (13.46) (44.45) (85.85) (101.60) (25.40) (8.64) (163.56) (17.53) (12.70) (25.40)

20SM12072 VEE 3/4 0.438 3.00 1.50 0.62 2.25 4.25 10.25 1.12 0.44 7.50 0.88 0.63 1.38

20SM12082 REG (19.05) (11.13) (76.20) (38.10) (15.75) (57.15) (107.95) (260.35) (28.45) (11.18) (190.50) (22.35) (16.00) (35.05)

20SM16072 VEE 1 0.562 4.12 2.06 0.63 2.81 5.12 10.25 1.62 0.56 9.00 1.25 1.13 1.75

20SM16082 REG (25.40) (14.27) (104.65) (52.32) (16.00) (71.37) (130.05) (260.35) (41.15) (14.22) (228.84) (31.75) (28.70) (44.4 5)

10SM9072 VEE 9/16 0.359 2.50 1.25 0.53 1.75 3.38 4.00 1.00 0.34 6.43 0.69 0.50 1.00

10SM9082 REG (14.29) (9.12) (63.50) (31.75) (13.46) (44.45) (85.85) (101.60) (25.40) (8.64) (163.56) (17.53) (12.70) (25.40)

10SM12072 VEE 3/4 0.516 3.00 1.50 0.62 2.25 4.25 10.25 1.12 0.44 7.50 0.88 0.63 1.38

10SM12082 REG (19.03) (13.11) (76.20) (38.10) (15.75) (57.15) (107.95) (260.35) (28.45) (11.18) (190.50) (22.35) (16.00) (35.05)

10SM16072 VEE 1 0.688 4.12 2.06 0.63 2.81 5.12 10.25 1.62 0.56 9.00 1.25 1.13 1.75

10SM16082 REG (25.40) (17.48) (104.65) (52.32) (16.00) (71.37) (130.05) (260.35) (41.15) (14.22) (228.84) (31.75) (28.70) (44.45)

3-Way / 2 on Pressure

20SM4073 VEE 1/4 0.125 2.00 1.00 0.38 1.63 1.19 2.63 3.00 0.75 0.22 5.00 0.62 0.38 0.75 See Figure 3

20SM4083 REG (6.35) (3.18) (50.80) (25.40) (9.65) (41.28) (30.23) (66.68) (76.20) (19.05) (5.59) (127.00) (15.75) (9.65) (19.05)

20SM6073 VEE 3/8 0.219 2.00 1.00 0.47 1.63 1.19 2.63 3.00 0.75 0.22 5.00 0.62 0.38 0.75

20SM6083 REG (9.53) (5.56) (50.80) (25.40) (11.94) (41.28) (30.23) (66.68) (76.20) (19.05) (5.59) (127.00) (15.75) (9.65) (19.05)

20SM9073 VEE 9/16 0.312 2.50 1.25 0.53 2.38 1.75 3.63 4.00 1.00 0.34 6.51 0.69 0.50 1.00

20SM9083 REG (14.29) (7.92) (63.50) (31.75) (13.46) (60.45) (44.45) (92.08) (101.60) (25.40) (8.64) (165.59) (17.53) (12.70) (25.40)

20SM12073 VEE 3/4 0.438 3.00 1.50 0.62 3.00 2.25 4.63 10.25 1.12 0.44 7.88 0.88 0.63 1.38

20SM12083 REG (19.05) (11.13) (76.20) (38.10) (15.75) (76.20) (57.15) (117.48) (260.35) (28.45) (11.18) (200.03) (22.35) (16.00) (35.05)

20SM16073 VEE 1 0.562 4.12 2.06 0.63 3.75 2.81 5.88 10.25 1.62 0.56 9.75 1.25 1.13 1.75

20SM16083 REG (25.40) (14.27) (104.65) (52.32) (16.00) (95.25) (71.37) (149.35) (260.35) (41.15) (14.22) (247.89) (31.75) (28.70) (44.4 5)

10SM9073 VEE 9/16 0.359 2.50 1.25 0.53 2.38 1.75 3.63 4.00 1.00 0.34 6.52 0.69 0.50 1.00

10SM9083 REG (14.29) (9.12) (63.50) (31.75) (13.46) (60.45) (44.45) (92.08) (101.60) (25.40) (8.64) (165.59) (17.53) (12.70) (25.40)

10SM12073 VEE 3/4 0.516 3.00 1.50 0.62 3.00 2.25 4.63 10.25 1.12 0.44 7.88 0.88 0.63 1.38

10SM12083 REG (19.03) (13.11) (76.20) (38.10) (15.75) (76.20) (57.15) (117.48) (260.35) (28.45) (11.18) (200.03) (22.35) (16.00) (35.05)

10SM16073 VEE 1 0.688 4.12 2.06 0.63 3.75 2.81 5.88 10.25 1.62 0.56 9.75 1.25 1.13 1.75

10SM16083 REG (25.40) (17.48) (104.65) (52.32) (16.00) (95.25) (71.37) (149.35) (260.35) (41.15) (14.22) (247.89) (31.75) (28.70) (44.45)

G - Packing gland mounting hole drill size * H Dimension is with stem in closed position. For prompt service, Autoclave

G1 - Bracket mounting hole size Panel mounting drill size: 0.22” all valves. All dimensions for reference only and subject to change. stock select products. Consult factory.

3-Way / 1 on Pressure

20SM4074 VEE 1/4 0.125 2.00 1.00 0.38 1.19 2.44 3.00 0.75 0.22 4.81 0.62 0.38 0.75 See Figure 4

20SM4084 REG (6.35) (3.18) (50.80) (25.40) (9.65) (30.23) (61.90) (76.20) (19.05) (5.59) (122.25) (15.75) (9.65) (19.05)

20SM6074 VEE 3/8 0.219 2.00 1.00 0.47 1.19 2.44 3.00 0.75 0.22 4.81 0.62 0.38 0.75

20SM6084 REG (9.53) (5.56) (50.80) (25.40) (11.94) (30.23) (61.90) (76.20) (19.05) (5.59) (122.25) (15.75) (9.65) (19.05)

20SM9074 VEE 9/16 0.312 2.50 1.25 0.53 1.75 3.38 4.00 1.00 0.34 6.31 0.69 0.50 1.00

20SM9084 REG (14.29) (7.92) (63.50) (31.75) (13.46) (44.45) (85.85) (101.60) (25.40) (8.64) (160.56) (17.53) (12.70) (25.40)

20SM12074 VEE 3/4 0.438 3.00 1.50 0.62 2.25 4.25 10.25 1.12 0.44 7.50 0.88 0.63 1.38

20SM12084 REG (19.05) (11.13) (76.20) (38.10) (15.75) (57.15) (107.95) (260.35) (28.45) (11.18) (190.50) (22.35) (16.00) (35.05)

20SM16074 VEE 1 0.562 4.12 2.06 0.63 2.81 5.21 10.25 1.62 0.56 9.09 1.25 1.13 1.75

20SM16084 REG (25.40) (14.27) (104.65) (52.32) (16.00) (71.37) (132.33) (260.35) (41.15) (14.22) (231.13) (31.75) (28.70) (44.4 5)

10SM9074 VEE 9/16 0.359 2.50 1.25 0.53 1.75 3.38 4.00 1.00 0.34 6.31 0.69 0.50 1.00

10SM9084 REG (14.29) (9.12) (63.50) (31.75) (13.46) (44.45) (85.85) (101.60) (25.40) (8.64) (160.56) (17.53) (12.70) (25.40)

10SM12074 VEE 3/4 0.516 3.00 1.50 0.62 2.25 4.25 10.25 1.12 0.44 7.50 0.88 0.63 1.38

10SM12084 REG (19.03) (13.11) (76.20) (38.10) (15.75) (57.15) (107.95) (260.35) (28.45) (11.18) (190.50) (22.35) (16.00) (35.05)

10SM16074 VEE 1 0.688 4.12 2.06 0.63 2.81 5.21 10.25 1.62 0.56 9.09 1.25 1.13 1.75

10SM16084 REG (25.40) (17.48) (104.65) (52.32) (16.00) (71.37) (132.33) (260.35) (41.15) (14.22) (231.13) (31.75) (28.70) (44.45)

2-Way Angle / Replaceable Seat

20SM4872 VEE 1/4 0.125 2.00 1.00 0.38 1.19 2.13 2.25 3.00 0.75 0.22 5.75 0.62 0.38 0.75 See Figure 5

20SM4882 REG (6.35) (3.18) (50.80) (25.40) (9.65) (30.23) (53.98) (57.15) (76.20) (19.05) (5.59) (146.05) (15.75) (9.65) (19.05)

20SM6872 VEE 3/8 0.219 2.00 1.00 0.47 1.19 2.13 2.25 3.00 0.75 0.22 5.75 0.62 0.38 0.75

20SM6882 REG (9.53) (5.56) (50.80) (25.40) (11.94) (30.23) (53.98) (57.15) (76.20) (19.05) (5.59) (146.05) (15.75) (9.65) (19.05)

20SM9872 VEE 9/16 0.312 2.50 1.25 0.53 1.75 2.50 3.13 4.00 1.00 0.34 7.34 0.69 0.50 1.00

20SM9882 REG (14.29) (7.92) (63.50) (31.75) (13.46) (44.45) (63.50) (79.38) (101.60) (25.40) (8.64) (186.68) (17.53) (12.70) (25.40)

20SM12872 VEE 3/4 0.438 3.00 1.50 0.62 2.25 3.44 4.25 10.25 1.12 0.44 9.00 0.88 0.63 1.38

20SM12882 REG (19.05) (11.13) (76.20) (38.10) (15.75) (57.15) (87.38) (107.95) (260.35) (28.45) (11.18) (228.60) (22.35) (16.00) (35.05)

20SM16872 VEE 1 0.562 4.12 2.06 0.63 2.69 4.38 5.21 10.25 1.62 0.56 11.00 1.25 1.13 1.75

20SM16882 REG (25.40) (14.27) (104.65) (52.32) (16.00) (68.33) (111.13) (133.35) (260.35) (41.15) (14.22) (279.64) (31.75) (28.70) (44.4 5)

10SM9872 VEE 9/16 0.359 2.50 1.25 0.53 1.75 2.50 3.38 4.00 1.00 0.34 7.34 0.69 0.50 1.00

10SM9882 REG (14.29) (9.12) (63.50) (31.75) (13.46) (44.45) (63.50) (85.85) (101.60) (25.40) (8.64) (186.68) (17.53) (12.70) (25.40)

10SM12872 VEE 3/4 0.516 3.00 1.50 0.62 2.25 3.44 4.25 10.25 1.12 0.44 9.00 0.88 0.63 1.38

10SM12882 REG (19.03) (13.11) (76.20) (38.10) (15.75) (57.15) (87.38) (107.95) (260.35) (28.45) (11.18) (228.60) (22.35) (16.00) (35.05)

10SM16872 VEE 1 0.688 4.12 2.06 0.63 2.69 4.38 5.25 10.25 1.62 0.56 11.00 1.25 1.13 1.75

10SM16882 REG (25.40) (17.48) (104.65) (52.32) (16.00) (68.33) (111.13) (133.35) (260.35) (41.15) (14.22) (279.64) (31.75) (28.70) (44.45)

G - Packing gland mounting hole drill size * H Dimension is with stem in closed position. For prompt service, Autoclave

G1 - Bracket mounting hole size All dimensions for reference only and subject to change. stock select products.

Panel mounting drill size: 0.22” all valves. Consult factory.

3-Way Angle / 2-Stem Manifold

20SM4075 VEE 1/4 0.125 2.00 1.00 0.38 1.69 1.19 3.38 3.00 0.75 0.22 8.13 0.62 0.38 0.75 See Figure 6

20SM4085 REG (6.35) (3.18) (50.80) (25.40) (9.65) (42.85) (30.15) (85.73) (76.20) (19.05) (5.59) (206.38) (15.75) (9.65) (19.05)

20SM6075 VEE 3/8 0.219 2.00 1.00 0.47 1.69 1.19 3.38 3.00 0.75 0.22 8.13 0.62 0.38 0.75

20SM6085 REG (9.53) (5.56) (50.80) (25.40) (11.94) (42.85) (30.15) (85.73) (76.20) (19.05) (5.59) (206.38) (15.75) (9.65) (19.05)

20SM9075 VEE 9/16 0.312 2.50 1.25 0.53 2.56 1.75 5.13 4.00 1.00 0.34 11.31 0.69 0.50 1.00

20SM9085 REG (14.29) (7.92) (63.50) (31.75) (13.46) (65.07) (44.45) (130.18) (101.60) (25.40) (8.64) (287.56) (17.53) (12.70) (25.40)

20SM12075 VEE 3/4 0.438 3.00 1.50 0.62 3.25 2.25 6.50 10.25 1.12 0.44 13.00 0.88 0.63 1.38

20SM12085 REG (19.05) (11.13) (76.20) (38.10) (15.75) (82.55) (57.15) (165.10) (260.35) (28.45) (11.18) (330.20) (22.35) (16.00) (35.05)

20SM16075 VEE 1 0.562 4.12 2.06 0.63 3.75 2.81 7.50 10.25 1.62 0.56 15.44 1.25 1.13 1.75

20SM16085 REG (25.40) (14.27) (104.65) (52.32) (16.00) (95.25) (71.37) (190.50) (260.35) (41.15) (14.22) (292.42) (31.75) (28.70) (44.4 5)

10SM9075 VEE 9/16 0.359 2.50 1.25 0.53 2.56 1.75 5.13 4.00 1.00 0.34 11.31 0.69 0.50 1.00

10SM9085 REG (14.29) (9.12) (63.50) (31.75) (13.46) (65.07) (44.45) (130.18) (101.60) (25.40) (8.64) (287.56) (17.53) (12.70) (25.40)

10SM12075 VEE 3/4 0.516 3.00 1.50 0.62 3.25 2.25 6.50 10.25 1.12 0.44 13.00 0.88 0.63 1.38

10SM12085 REG (19.03) (13.11) (76.20) (38.10) (15.75) (82.55) (57.15) (165.10) (260.35) (28.45) (11.18) (330.20) (22.35) (16.00) (35.05)

10SM16075 VEE 1 0.688 4.12 2.06 0.63 3.75 2.81 7.50 10.25 1.62 0.56 15.44 1.25 1.13 1.75

10SM16085 REG (25.40) (17.48) (104.65) (52.32) (16.00) (95.25) (71.37) (190.50) (260.35) (41.15) (14.22) (392.42) (31.75) (28.70) (44.45)

G - Packing gland mounting hole drill size * H Dimension is with stem in closed position. For prompt service, Autoclave

G1 - Bracket mounting hole size All dimensions for reference only and subject to change. stock select products.

Panel mounting drill size: 0.22” all valves. Consult factory.

Needle Valves

High Pressure

30SC, 30VM, 40VM, 60VM, 100V, & 150V Series

Pressures to 150,000 psi (10342 bar)

Since 1945, Autoclave Engineers has designed and built premium quality valves, fittings and tubing. This commitment to engineering and manufacturing excellence has earned Autoclave a reputation for reliable and efficient product performance. Autoclave Engineers has long been established as the worldwide leader in high pressure fluid handling components for the chemical/petrochemical, research, oil and gas, waterjet, and waterblast industries.

www.autoclaveengineers.com

Needle Valves -High Pressure

High Pressure Valve Features

.

Tubing sizes from 1/4” to 1”.

.

Non-rotating stem prevents stem/seat galling.

.

Rising stem/barstock body design.

.

Metal-to-metal seating achieves bubble-tight shut-off, longer stem/seat life in abrasive flow, greater

durability for repeated on/off cycles and excellent corrosion resistance.

.

For dependable stem and body sealing 30SC and 30VM valves are furnished with PTFE (Teflon) encapsulated packing; the 40VM and 60VM valves feature nylon/leather packing below threads.

.

Stem sleeve and packing gland materials have been selected to achieve extended thread cycle life and reduced handle torque.

.

Choice of Vee or Regulating stem tips.

Series 100V: Pressures to 100,000 psi (6895 bar) features:

.

Cold-worked type 316 stainless steel body with aluminum bronze packing gland and non-rotating stem.

.

Nylon and leather packing below stem threads.

Series 150V: Pressures to 150,000 psi (10342 bar) features:

.

Cylindrical body of high strength alloy steel with stainless steel packing gland. Tool steel non-rotating stem with replaceable seat of nickel maraging steel. Stem must be actuated with torque wrench (refer to Tools, Installation, Operation and Maintenance section).

.

Wedge-type Teflon and leather packing below stem threads with beryllium-copper Autoclave

Anti-Extrusion Back up Rings.

.

Vee stem tip only

Autoclave valves are complemented by a complete line of high pressure fittings and tubing. The high pressure series uses Autoclave’s coned-and-threaded connections for dependable performance in gas or liquid service.

Needle Valves -30SC Series

Pressures to 30,000 psi (2068 bar)

Number of tur

n

s ope

For complete information on available stem types, optional connections and additional valve options, see Needle Valve Options section or contact your Sales Representative. The 30SC Series valves are furnished complete with connection components, unless otherwise specified.

Vee stem (on-off service)

regulating stem (tapered tip for regulating and shutoff) 87 -Vee stem with replaceable

All general terms and conditions of sale, including limitations of our liability, apply to all products and services sold.

Pressure/ Tube Temperature Outside Rating Diameter Orifice psi (bar) Size Connection Size Rated @ Room Inches Type Inches (mm) Cv*Temperature**

1 SF1000CX43 .438 (11.12) 2.6 30,000 (2068)

Notes: *CV values shown are for 2-way straight valve pattern. For 2-way angle patterns, increase CV value 50%. ** For complete temperature ratings see pressure/temperature rating guide in Technical Information section.

0

10

% of rated Cv

6 5

4 3 2 1

To ensure proper fit use Autoclave tubing

Ordering Procedure

Typical catalog number: 30SC16071

30SC 16 07

1 Options

Valve Outside Diameter Stem/Seat Body Options

Series Tube Size Type Pattern

For extreme

1 -two-way straight

16-1” 07 -non-rotating temperature and other2 -two-way angle options, see Valve 08 -non-rotating Options.

seat

88 -Regulating stem with replaceable seat

Valve Options

Valve Maintenance

Extreme Temperatures

Standard Autoclave valves with Teflon packing may be operated to

450°F (232°C). High temperature packing is available for service

from -423°F (-252°C) to 1200°F (649°C) by adding the following

suffixes to catalog order number.

TG -standard valve with Teflon glass packing to 600°F (316°C).

GY -standard valve with graphite braided yarn packing to 800°F (427°C).

HT -extended stuffing box valve with graphite braided yarn packing to 1200°F (649°C).

B -standard valve with cryogenic trim material and Teflon packing to -100°F (-73°C).

LT -extended stuffing box valve with Teflon packing & Cryogenic trim materials to

-423°F (-252°C).

2-Way Straight

Repair Kits: add “R” to the front of valve catalog number for proper repair kit. (Example: R30SC16071)

Valve Bodies: Valve bodies are available. Order using the eight (8) digit part number found in the valve drawing or contact your Sales Representative for information.

Consult your Autoclave representative for pricing on repair kits and valve bodies. Refer to the Tools, Installation, Operation and Maintenance section for proper maintenance procedures.

30SC16071 VEE 1” 0.438 4.13 2.06 0.72 3.50 2.75 4.44 10.25 1.62 0.56 8.42 1.25 1.12 1.75

30SC16081 REG (25.40) (11.12) (104.90) (52.32) (18.28) (88.90) (69.85) (112.77) (260.35) (41.14) (14.22) (213.86) (31.75) (28.44) (44.45)

See

Figure 1

2-Way Angle

30SC16072 VEE 1” 0.438 4.13 2.06 0.72 2.75 5.12 10.25 1.62 0.56 9.35 1.25 1.12 1.75

30SC16082 REG (25.40) (11.12) (104.90) (52.32) (18.28) (69.85) (130.04) (260.35) (41.14) (14.22) (237.49) (31.75) (28.44) (44.45)

See

Figure 2

2-Way Angle/Replaceable Seat

30SC16872 VEE 1”

0.438

4.13

2.06

0.72

2.81

4.31

5.12

7.00

1.62

0.56

10.56

1.25

1.12

1.75

30SC16882 REG

(25.40)

(11.12)

(104.90) (52.32)

(18.28)

(71.37)

(109.47) (130.04)

(177.80)

(41.14)

(14.22)

(268.22)

(31.75)

(28.44)

(44.45)

See Figure 3

G - Packing gland mounting hole drill size All dimensions for reference only and subject to change. For prompt service, Autoclave stocks G1 - Bracket mounting hole size *H Dimesion is with stem in closed position select products. Consult factory. Panel mounting drill size: 0.22” all valves.

Needle Valves -30VM Series

ns open

Number of tur

All general terms and conditions of sale, including limitations of our liability, apply to all products and services sold.

Pressure/ Tube Temperature Outside Rating Diameter Orifice psi (bar) Size Connection Size Rated @ Room Inches Type Inches (mm) Cv*Temperature**

1/4 F250C 0.094 (2.39) 0.12 30,000 (2068) 3/8 F375C 0.125 (3.18) 0.23 30,000 (2068) 9/16 F562C 0.125 (3.18) 0.33 30,000 (2068)

Notes: *CV values shown are for 2-way straight valve pattern. For 2-way angle patterns, increase CV value 50%. ** For complete temperature ratings see pressure/temperature rating guide in Technical Information section.

To ensure proper fit use Autoclave tubing

Ordering Procedure

Typical catalog number: 30VM4071

Options

Valve Outside Diameter Stem/Seat Body Options

Series Tube Size Type Pattern

For extreme4-1/4” 07 -non-rotating 1 -two-way straight temperature and other6-3/8” 2 -two-way angle options, see Valve 9-9/16” 08 -non-rotating 3 -three-way, two on pressure Options.

4 -three-way, one on pressure

5 -three-way, two-stem

manifold valve

seat

88 -Regulating stem with replaceable seat

Valve Options

Extreme Temperatures

Standard Autoclave valves with Teflon packing may be operated to

450°F (232°C). High temperature packing is available for service

from -423°F (-252°C) to 1200°F (644°C) by adding the following

suffixes to catalog order number.

TG -standard valve with Teflon glass packing to 600°F (316°C).

GY -standard valve with graphite braided yarn packing to 800°F (427°C).

HT -extended stuffing box valve with graphite braided yarn packing to 1200°F (649°C).

B -standard valve with cryogenic trim material and Teflon packing to -100°F (-73°C).

LT -extended stuffing box valve with Teflon packing & Cryogenic trim materials to

-423°F (-252°C).

2-Way Straight

Valve Maintenance

Repair Kits: add “R” to the front of valve catalog number for proper repair kit. (Example: R30VM4071)

Valve Bodies: Valve bodies are available. Order using the eight (8) digit part number found in the valve drawing or contact your Sales Representative for information.

Consult your Autoclave representative for pricing on repair kits and valve bodies. Refer to the Tools, Installation, Operation and Maintenance section for proper maintenance procedures.

30VM4071 VEE 1/4 0.094 2.00 1.00 0.50 1.50 1.12 2.00 3.00 1.00 0.22 4.62 0.69 0.38 1.00 See Figure 1

30VM4081 REG (6.35) (2.39) (50.80) (25.40) (12.70) (38.10) (28.45) (50.80) (76.20) (25.40) (5.59) (117.35) (17.53) (9.65) (25.40)

30VM6071 VEE 3/8 0.125 2.00 1.00 0.53 1.50 1.12 2.00 3.00 1.00 0.22 4.68 0.69 0.38 1.00

30VM6081 REG (9.53) (3.18) (50.80) (25.40) (13.46) (38.10) (28.45) (50.80) (76.20) (25.40) (5.59) (118.87) (17.53) (9.65) (25.40)

30VM9071 VEE 9/16 0.125 2.62 1.31 0.81 1.56 1.12 2.44 3.00 1.00 0.28 5.06 0.69 0.38 1.50

30VM9081 REG (14.29) (3.18) (66.55) (33.27) (20.57) (39.62) (28.45) (61.98) (76.20) (25.40) (7.11) (128.52) (17.53) (9.65) (38.10)

2-Way Angle

3-Way / 2 on Pressure

30VM4072 VEE 1/4 0.094 2.00 1.00 0.50 1.12 2.00 3.00 1.00 0.22 4.62 0.69 0.38 1.00 See Figure 2

30VM4082 REG (6.35) (2.39) (50.80) (25.40) (12.70) (28.45) (50.80) (76.20) (25.40) (5.59) (117.35) (17.53) (9.65) (25.40)

30VM6072 VEE 3/8 0.125 2.00 1.00 0.53 1.12 2.12 3.00 1.00 0.22 4.74 0.69 0.38 1.00

30VM6082 REG (9.53) (3.18) (50.80) (25.40) (13.46) (28.45) (53.85) (76.20) (25.40) (5.59) (120.40) (17.53) (9.65) (25.40)

30VM9072 VEE 9/16 0.125 2.62 1.31 0.81 1.12 2.44 3.00 1.00 0.28 5.06 0.69 0.38 1.50

30VM9082 REG (14.29) (3.18) (66.55) (33.27) (20.57) (28.45) (61.98) (76.20) (25.40) (7.11) (128.52) (17.53) (9.65) (38.10)

30VM4073 VEE 1/4 0.094 2.00 1.00 0.50 1.50 1.12 2.12 3.00 1.00 0.22 4.74 0.69 0.38 1.00 See Figure 3

30VM4083 REG (6.35) (2.39) (50.80) (25.40) (12.70) (38.10) (28.45) (53.85) (76.20) (25.40) (5.59) (120.40) (17.53) (9.65) (25.40)

30VM6073 VEE 3/8 0.125 2.00 1.00 0.53 1.50 1.12 2.50 3.00 1.00 0.22 5.12 0.69 0.38 1.00

30VM6083 REG (9.53) (3.18) (50.80) (25.40) (13.46) (38.10) (28.45) (63.50) (76.20) (25.40) (5.59) (130.05) (17.53) (9.65) (25.40)

30VM9073 VEE 9/16 0.125 2.62 1.31 0.81 1.56 1.12 2.88 3.00 1.00 0.28 5.49 0.69 0.38 1.50

30VM9083 REG (14.29) (3.18) (66.55) (33.27) (20.57) (39.62) (28.45) (73.15) (76.20) (25.40) (7.11) (139.45) (17.53) (9.65) (38.10)

G - Packing gland mounting hole drill size All dimensions for reference only and subject to change. For prompt service,

G1 - Bracket mounting hole size * H Dimension is with stem in the closed position. Autoclave stocks select products.

Panel mounting drill size: 0.22” all valves. Consult factory.

3-Way / 1 on Pressure

30VM4074 VEE 1/4 0.094 2.00 1.00 0.50 1.12 2.00 3.00 1.00 0.22 4.62 0.69 0.38 1.00 See Figure 4

30VM4084 REG (6.35) (2.39) (50.80) (25.40) (12.70) (28.45) (50.80) (76.20) (25.40) (5.59) (117.35) (17.53) (9.65) (25.40)

30VM6074 VEE 3/8 0.125 2.00 1.00 0.53 1.12 2.12 3.00 1.00 0.22 4.74 0.69 0.38 1.00

30VM6084 REG (9.53) (3.18) (50.80) (25.40) (13.46) (28.45) (53.85) (76.20) (25.40) (5.59) (120.40) (17.53) (9.65) (25.40)

30VM9074 VEE 9/16 0.125 2.62 1.31 0.81 1.12 2.44 3.00 1.00 0.28 5.12 0.69 0.38 1.50

30VM9084 REG (14.29) (3.18) (66.55) (33.27) (20.57) (28.45) (61.98) (76.20) (25.40) (7.11) (130.05) (17.53) (9.65) (38.10)

2-Way Angle / Replaceable Seat

30VM4872 VEE 1/4 0.094 2.00 1.00 0.50 1.12 2.06 2.38 3.00 1.00 0.22 5.80 0.69 0.38 1.00 See Figure 5

30VM4882 REG (6.35) (2.39) (50.80) (25.40) (12.70) (28.45) (52.32) (60.45) (76.20) (25.40) (5.59) (147.32) (17.53) (9.65) (25.40)

30VM6872 VEE 3/8 0.125 2.00 1.00 0.53 1.12 2.31 2.38 3.00 1.00 0.22 6.05 0.69 0.38 1.00

30VM6882 REG (9.53) (3.18) (50.80) (25.40) (13.46) (28.45) (58.67) (60.45) (76.20) (25.40) (5.59) (153.67) (17.53) (9.65) (25.40)

30VM9872 VEE 9/16 0.125 2.62 1.31 0.81 1.19 2.62 2.44 3.00 1.00 0.28 6.45 0.69 0.38 1.50

30VM9882 REG (14.29) (3.18) (66.55) (33.27) (20.57) (30.23) (66.55) (61.98) (76.20) (25.40) (7.11) (163.83) (17.53) (9.65) (38.10)

3-Way / 2-Stem Manifold

30VM4075 VEE 1/4 0.094 2.00 1.00 0.50 1.53 1.12 3.06 3.00 1.00 0.22 5.68 0.69 0.38 1.00 See Figure 6

30VM4085 REG (6.35) (2.39) (50.80) (25.40) (12.70) (38.86) (28.45) (77.72) (76.20) (25.40) (5.59) (144.27) (17.53) (9.65) (25.40)

30VM6075 VEE 3/8 0.125 2.00 1.00 0.53 1.62 1.12 3.25 3.00 1.00 0.22 5.87 0.69 0.38 1.00

30VM6085 REG (9.53) (3.18) (50.80) (25.40) (13.46) (41.15) (28.45) (82.55) (76.20) (25.40) (5.59) (149.10) (17.53) (9.65) (25.40)

30VM9075 VEE 9/16 0.125 2.62 1.31 0.81 1.88 1.12 3.75 3.00 1.00 0.28 6.37 0.69 0.38 1.50

30VM9085 REG (14.29) (3.18) (66.55) (33.27) (20.57) (47.75) (28.45) (95.25) (76.20) (25.40) (7.11) (161.80) (17.53) (9.65) (38.10)

G - Packing gland mounting hole drill size All dimensions for reference only and subject to change. For prompt service,

G1 - Bracket mounting hole size * H Dimension is with stem in the closed position. Autoclave stocks select products.

Panel mounting drill size: 0.22” all valves. Consult factory.

Needle Valves -40VM Series

Pressures to 40,000 psi (2760 bar)

ns open

Number of tur

All general terms and conditions of sale, including limitations of our liability, apply to all products and services sold.

Pressure/ Tube Temperature Outside Rating Diameter Orifice psi (bar) Size Connection Size Rated @ Room Inches Type Inches (mm) Cv*Temperature**

9/16 F562C40 0.109 (2.77) 0.28 40,000 (2760)

Notes: *CV values shown are for 2-way straight valve pattern. For 2-way angle patterns, increase CV value 50%. ** For complete temperature ratings see pressure/temperature rating guide in Technical Information section.

6 5 4

0

10

% of rated Cv

3 2 1

To ensure proper fit use Autoclave tubing

Ordering Procedure

Typical catalog number: 40VM9071

Options

Valve Outside Diameter Stem/Seat Body Options

Series Tube Size Type

9-9/16” 07 -non-rotating

Pattern

For extreme

1 -two-way straight

2 -two-way angle temperature and other

options, see Valve 08 -non-rotating 3 -three-way angle, Options.

two-stem manifold valve

Valve Options

Valve Maintenance

Extreme Temperatures

Standard Autoclave valves with Teflon packing may be operated to

450°F (232°C). High temperature packing is available for service

from -423°F (-252°C) to 1200°F (649°C) by adding the following

suffixes to catalog order number.

TG -standard valve with Teflon glass packing to 600°F (316°C).

GY -standard valve with graphite braided yarn packing to 800°F (427°C).

HT -extended stuffing box valve with graphite braided yarn packing to 1200°F (649°C).

B -standard valve with cryogenic trim material and Teflon packing to -100°F (-73°C).

LT -extended stuffing box valve with Teflon packing & Cryogenic trim materials to

-423°F (-252°C).

2-Way Straight

Repair Kits: add “R” to the front of valve catalog number for proper repair kit. (Example: R40VM9071)

Valve Bodies: Valve bodies are available. Order using the eight (8) digit part number found in the valve drawing or contact your Sales Representative for information.

Consult your Autoclave representative for pricing on repair kits and valve bodies. Refer to the Tools, Installation, Operation and Maintenance section for proper maintenance procedures.

40VM9071 VEE 9/16 0.109 2.62 1.31 0.72 1.75 1.31 2.50 3.00 1.00 0.28 5.06 0.69 0.38 1.50

40VM9081 REG (14.3) (2.77) (66.55) (33.27) (18.29) (44.45) (33.27) (63.50) (76.20) (25.40) (7.11) (128.52) (17.53) (9.65) (38.10)

See

Figure 1

2-Way Angle

40VM9072 VEE 9/16 0.109 2.62 1.31 0.72 1.31 2.81 3.00 1.00 0.28 5.37 0.69 0.38 1.50

40VM9082 REG (14.3) (2.77) (66.55) (33.27) (18.29) (33.27) (71.37) (76.20) (25.40) (7.11) (136.40) (17.53) (9.65) (38.10)

See

Figure 2

3-Way / 2 Stem Manifold

40VM9075 VEE 9/16 0.109 2.62 1.31 0.72 2.06 1.31 4.12 3.00 1.00 0.28 9.12 0.69 0.38 1.50

40VM9085 REG (14.3) (2.77) (66.55) (33.27) (18.29) (52.32) (33.27) (104.65) (76.20) (25.40) (7.11) (231.65) (17.53) (9.65) (38.10)

See

Figure 3

G - Packing gland mounting hole drill size All dimensions for reference only and subject to change. For prompt service, Autoclave stocks

G1 - Bracket mounting hole size * H Dimension is with stem in the closed position select products. Consult factory.

Panel mounting drill size: 0.22” all valves.

Needle Valves -60VM Series

ns open

Number of tur

All general terms and conditions of sale, including limitations of our liability, apply to all products and services sold.

Pressure/ Tube Temperature Outside Rating Diameter Orifice psi (bar) Size Connection Size Rated @ Room Inches Type Inches (mm) Cv*Temperature**

1/4 F250C 0.062 (1.57) 0.08 60,000 (4137) 3/8 F375C 0.062 (1.57) 0.09 60,000 (4137) 9/16 F562C 0.078 (1.98) 0.14 60,000 (4137)

Notes: *CV values shown are for 2-way straight valve pattern. For 2-way angle patterns, increase CV value 50%. ** For complete temperature ratings see pressure/temperature rating guide in Technical Information section.

% of rated Cv

Ordering Procedure

Typical catalog number: 60VM4071

Options

Valve Outside Diameter Stem/Seat Body Options

Series Tube Size Type

Pattern

For extreme

1 -two-way straight

4-1/4” 07 -non-rotating temperature and other6-3/8” 2 -two-way angle options, see Valve 9-9/16” 08 -non-rotating 3 -three-way, two on pressure Options.

4 -three-way, one on pressure

5 -three-way, two-stem

manifold valve

seat

88 -Regulating stem with replaceable seat

Valve Options

Extreme Temperatures

Standard Autoclave valves with Teflon packing may be operated to

450°F (232°C). High temperature packing is available for service

from -423°F (-252°C) to 1200°F (649°C) by adding the following

suffixes to catalog order number.

TG -standard valve with Teflon glass packing to 600°F (316°C).

GY -standard valve with graphite braided yarn packing to 800°F (427°C).

HT -extended stuffing box valve with graphite braided yarn packing to 1200°F (649°C).

B -standard valve with cryogenic trim material and Teflon packing to -100°F (-73°C).

LT -extended stuffing box valve with Teflon packing & Cryogenic trim materials to

-423°F (-252°C).

2-Way Straight

Valve Maintenance

Repair Kits: add “R” to the front of valve catalog number for proper repair kit. (Example: R60VM4071)

Valve Bodies: Valve bodies are available. Order using the eight (8) digit part number found in the valve drawing or contact your Sales Representative for information.

Consult your Autoclave representative for pricing on repair kits and valve bodies. Refer to the Tools, Installation, Operation and Maintenance section for proper maintenance procedures.

60VM4071 VEE 1/4 0.062 2.00 1.00 0.50 1.69 1.31 2.12 3.00 1.00 0.22 4.75 0.69 0.38 1.00 See Figure 1

60VM4081 REG (6.35) (1.57) (50.80) (25.40) (12.70) (42.93) (33.27) (53.85) (76.20) (25.40) (5.59) (120.65) (17.53) (9.65) (25.40)

60VM6071 VEE 3/8 0.062 2.00 1.00 0.53 1.69 1.31 2.25 3.00 1.00 0.22 4.87 0.69 0.38 1.00

60VM6081 REG (9.53) (1.57) (50.80) (25.40) (13.46) (42.93) (33.27) (57.15) (76.20) (25.40) (5.59) (123.70) (17.53) (9.65) (25.40)

60VM9071 VEE 9/16 0.078 2.62 1.31 0.72 1.75 1.31 2.50 3.00 1.00 0.28 5.13 0.69 0.38 1.50

60VM9081 REG (14.29) (1.98) (66.55) (33.27) (18.29) (45.45) (33.27) (63.50) (76.20) (25.40) (7.11) (130.30) (17.53) (9.65) (38.10)

2-Way Angle

3-Way / 2 on Pressure

60VM4072 VEE 1/4 0.062 2.00 1.00 0.50 1.31 2.38 3.00 1.00 0.22 5.00 0.69 0.38 1.00 See Figure 2

60VM4082 REG (6.35) (1.57) (50.80) (25.40) (12.70) (33.27) (60.45) (76.20) (25.40) (5.59) (127.00) (17.53) (9.65) (25.40)

60VM6072 VEE 3/8 0.062 2.00 1.00 0.53 1.31 2.62 3.00 1.00 0.22 5.25 0.69 0.38 1.00

60VM6082 REG (9.53) (1.57) (50.80) (25.40) (13.46) (33.27) (66.55) (76.20) (25.40) (5.59) (133.35) (17.53) (9.65) (25.40)

60VM9072 VEE 9/16 0.078 2.62 1.31 0.72 1.31 2.81 3.00 1.00 0.28 5.44 0.69 0.38 1.50

60VM9082 REG (14.29) (1.98) (66.55) (33.27) (18.29) (33.27) (71.37) (76.20) (25.40) (7.11) (138.18) (17.53) (9.65) (38.10)

60VM4073 VEE 1/4 0.062 2.00 1.00 0.50 1.69 1.31 2.12 3.00 1.00 0.22 4.75 0.69 0.38 1.00 See Figure 3

60VM4083 REG (6.35) (1.57) (50.80) (25.40) (12.70) (42.93) (33.27) (53.85) (76.20) (25.40) (5.59) (120.65) (17.53) (9.65) (25.40)

60VM6073 VEE 3/8 0.062 2.00 1.00 0.53 1.69 1.31 2.25 3.00 1.00 0.22 4.87 0.69 0.38 1.00

60VM6083 REG (9.53) (1.57) (50.80) (25.40) (13.46) (42.93) (33.27) (57.15) (76.20) (25.40) (5.59) (123.70) (17.53) (9.65) (25.40)

60VM9073 VEE 9/16 0.078 2.62 1.31 0.72 1.75 1.31 2.50 3.00 1.00 0.28 5.13 0.69 0.38 1.50

60VM9083 REG (14.29) (1.98) (66.55) (33.27) (18.29) (45.45) (33.27) (63.50) (76.20) (25.40) (7.11) (130.30) (17.53) (9.65) (38.10)

G - Packing gland mounting hole drill size All dimensions for reference only and subject to change. For prompt service,

G1 - Bracket mounting hole size * H Dimension is with stem in the closed position. Autoclave stocks select products.

Panel mounting drill size: 0.22” all valves. Consult factory.

3-Way / 1 on Pressure

60VM4074 VEE 1/4 0.062 2.00 1.00 0.50 1.31 2.38 3.00 1.00 0.22 5.00 0.69 0.38 1.00 See Figure 4

60VM4084 REG (6.35) (1.57) (50.80) (25.40) (12.70) (33.27) (60.45) (76.20) (25.40) (5.59) (127.00) (17.53) (9.65) (25.40)

60VM6074 VEE 3/8 0.062 2.00 1.00 0.53 1.31 2.62 3.00 1.00 0.22 5.25 0.69 0.38 1.00

60VM6084 REG (9.53) (1.57) (50.80) (25.40) (13.46) (33.27) (66.55) (76.20) (25.40) (5.59) (133.35) (17.53) (9.65) (25.40)

60VM9074 VEE 9/16 0.078 2.62 1.31 0.72 1.31 2.81 3.00 1.00 0.28 5.44 0.69 0.38 1.50

60VM9084 REG (14.29) (1.98) (66.55) (33.27) (18.29) (33.27) (71.37) (76.20) (25.40) (7.11) (138.18) (17.53) (9.65) (38.10)

2-Way Angle / Replaceable Seat

60VM4872 VEE 1/4 0.062 2.00 1.00 0.50 1.31 2.12 2.62 3.00 1.00 0.22 6.28 0.69 0.38 1.00 See Figure 5

60VM4882 REG (6.35) (1.57) (50.80) (25.40) (12.70) (33.27) (53.85) (66.55) (76.20) (25.40) (5.59) (159.51) (17.53) (9.65) (25.40)

60VM6872 VEE 3/8 0.062 2.00 1.00 0.53 1.31 2.36 2.62 3.00 1.00 0.22 6.52 0.69 0.38 1.00

60VM6882 REG (9.53) (1.57) (50.80) (25.40) (13.46) (33.27) (59.94) (66.55) (76.20) (25.40) (5.59) (165.60) (17.53) (9.65) (25.40)

60VM9872 VEE 9/16 0.078 2.62 1.31 0.72 1.31 2.68 2.62 3.00 1.00 0.28 6.90 0.69 0.38 1.50

60VM9882 REG (14.29) (1.98) (66.55) (33.27) (18.29) (33.27) (68.07) (66.55) (76.20) (25.40) (7.11) (175.26) (17.53) (9.65) (38.10)

3-Way / 2-Stem Manifold

60VM4075 VEE 1/4 0.062 2.00 1.00 0.50 1.72 1.31 3.44 3.00 1.00 0.22 6.07 0.69 0.38 1.00 See Figure 6

60VM4085 REG (6.35) (1.57) (50.80) (25.40) (12.70) (43.69) (33.27) (87.38) (76.20) (25.40) (5.59) (154.18) (17.53) (9.65) (25.40)

60VM6075 VEE 3/8 0.062 2.00 1.00 0.53 1.88 1.31 3.75 3.00 1.00 0.22 6.37 0.69 0.38 1.00

60VM6085 REG (9.53) (1.57) (50.80) (25.40) (13.46) (47.75) (33.27) (95.25) (76.20) (25.40) (5.59) (161.80) (17.53) (9.65) (25.40)

60VM9075 VEE 9/16 0.078 2.62 1.31 0.72 2.06 1.31 4.12 3.00 1.00 0.28 6.37 0.69 0.38 1.50

60VM9085 REG (14.29) (1.98) (66.55) (33.27) (18.29) (52.32) (33.27) (104.65) (76.20) (25.40) (7.11) (161.80) (17.53) (9.65) (38.10)

G - Packing gland mounting hole drill size All dimensions for reference only and subject to change. For prompt service,

G1 - Bracket mounting hole size * H Dimension is with stem in the closed position. Autoclave stocks select products.

Panel mounting drill size: 0.22” all valves. Consult factory.

Pressures to 150,000 psi (10350 bar)

Needle Valves -100VM & 150V Series

Number of tur

ns open

Pressure/ Tube Temperature Outside Rating Diameter Orifice psi (bar) Size Connection Size Rated @ Room Inches Type Inches (mm) Cv*Temperature**

Series 100VM 5/16 F312C150 0.094 (2.39) .17 100,000 (6895) Series 150V 5/16 F312C150 0.062 (1.57) .27 150,000 (10342)

Notes: *CV values shown are for 2-way straight valve pattern. For 2-way angle patterns, increase CV value 50%. ** For complete temperature ratings see pressure/temperature rating guide in Technical Information section.

Generalized Flow Coefficient Curves (Cv)

7 6 5

4 3 2

V ee Stem 100V

150V

1020 3040 5060 708090100 % of rated Cv

Notes: Torque wrench required to operate valves.

SEATING

100VM Series 150V Series

To ensure proper fit use Autoclave tubing All general terms and conditions of sale, including limitations of our liability, apply to all products and services sold.

Ordering Procedure

For complete information on available stem types, optional connections and additional valve options, see Needle Valve Options section or contact your Sales Representative. The 100V Series valves are furnished complete with connection components, unless otherwise specified.

Typical catalog number: 100VM5071

100VM 5 1 Options

Valve Outside Diameter Stem Body Options

Series Tube Size Type Pattern

100VM 150V 5-5/16” 07 -non-rotating Vee stem (on off service) 1 -two-way straight 2 -two-way angle For extreme temperature and other options, see Valve

3 -three-way, two on pressure Options.

Valve Options Valve Maintenance

Extreme Temperatures Repair Kits: add “R” to the front of valve catalog

Standard AE valves with Teflon packing may be operated to 450°F number for proper repair kit. (232°C), and to 230°F (110°C) with nylon-leather packing. For (Example: R100VM15071)

other packing options consult the factory. Valve Bodies: Valve bodies are available. Order using the eight (8) digit part number found in the valve drawing or contact your Sales Representative for information.

Consult your Autoclave representative for pricing on repair kits and valve bodies. Refer to the Tools, Installation, Operation and Maintenance section for proper maintenance procedures.

2-Way Straight

See

100VM5071

VEE

5/16 0.094

3.00

1.50

0.52

1.75

1.44

2.25

4.00

1.12

0.34

5.32

1.12

0.50

1.38

Figure 1

(7.93)

(2.39)

(76.20)

(38.10)

(13.21)

(44.45)

(36.58)

(57.15)

(101.60)

(28.45)

(8.64)

(135.13)

(28.45)

(12.70)

(35.05)

2-Way Angle

G - Packing gland mounting hole drill size All dimensions for reference only and subject to change. For prompt service,

G1 - Bracket mounting hole size * H Dimension is with stem in the closed position. Autoclave stocks select products.

Panel mounting drill size: 0.22” all valves. Consult factory.

3-Way / 2 On Pressure

100VM5073 VEE 5/16 0.094 3.00 1.50 0.52 1.75 1.44 3.25 4.00 1.12 0.34 6.31 1.12 0.50 1.38

(7.93) (2.39) (76.20) (38.10) (13.21) (44.45) (36.58) (82.55) (101.60) (28.45) (8.64) (160.27) (28.45) (12.70) (35.05)

See

Figure 3

2-Way Angle / Replaceable Seat 150V5072 VEE 5/16 0.062 3.75 1.88 2.25 2.63 4.00 1.44 7.12 1.25 (7.93) (1.57) (95.25) (47.63) (57.15) (66.80) (101.60) (36.50) (180.85) (31.75) See Figure 4

G - Packing gland mounting hole drill size All dimensions for reference only and subject to change. For prompt service, G1 - Bracket mounting hole size * H Dimension is with stem in the closed position. Autoclave stocks select products. Panel mounting drill size: 0.22” all valves. Consult factory.

Needle Valves

Mini Valves

MVE/MV Series

Pressures to 15,000 psi (1034 bar)