|

|

|

|

派克汉尼汾 | Pick深海液压快换接头,这三个问题你遇到过吗?

Subsea Connection Systems - Parker Hannifin

在浅海、深海和超深海域油气应用中,选择合适的液压快换接头至关重要。为了实现液压快换接头安全可靠的连接,密封、水深、插拔力和材料选择等诸多因素均需考虑。

在本期的小派课堂,我们特地为大家整理了深海液压快换接头选用过程中出现的一些疑问合辑,快来看看你是不是也get过同款问题。

1. 液压快换接头的内部压力为10000 psi,需在 3000米的深海将其连接,在平台上部模块压力为0 psi时将其断开,应选用什么类型的密封件?哪种产品可以满足这样的要求?

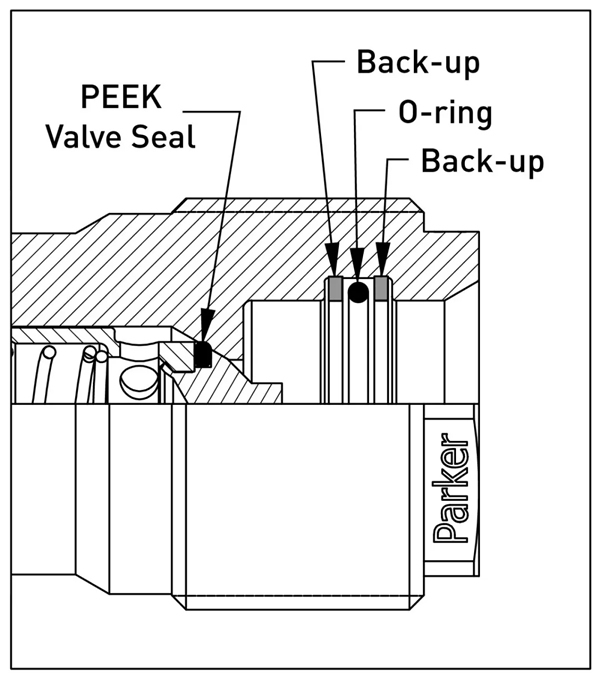

在3000米的深海之中,工作接头的内部压力将高于外部压力(3000米=4388 psi)5000psi,阀体密封在连接时会受到高速流体的冲击。因此,它们需由诸如PEEK之类坚固的热塑材料制成,同时牢固地依附在阀体上。

派克汉尼汾深海快换接头产品样本中的大多数产品均采用这种阀体密封,可在压力下进行连接。由于断开时平台上部模块压力为0 psi,您可选择配置O形圈加双侧挡圈结构、阀体密封响应及时的快换接头。派克汉尼汾旗下的DSE系列配备PEEK阀体密封、O形圈加双侧挡圈密封结构,阀体密封响应及时,性价比也高。

2. 我曾读过一些有关深海快换接头低插拔力的文章,相比传统的深海快换接头,派克产品的插拔力到底有多低呢?

低插拔力快换产品可将插拔力降低55%。比如, 1/2”规格的传统 DSC快换接头,其插拔力为695 lb/1000psi。而同样为?”规格的低插拔力DSL快换接头,其插拔力仅为307lb/1000psi。DSL替换DSC系列后,Cv值将从2提高到3,这是新型快换产品带来的优势。

3. 某个应用选用了316不锈钢材质的快换接头。那么,在深海应用中,是否能选择标准快换产品样本中的316不锈钢非溢出型快换接头?

如果条件合适,非深海应用的快换接头产品可用于深海应用。通常,需要考虑的主要问题是外部压力不能高于内部工作压力500psi,因为密封件正常工作的前提条件为内部压力高于外部压力。

在压力下连接和断开快换产品、预期使用寿命以及其它因素也要纳入考虑范围。若将非深海应用的快换产品用于深海应用,小派建议您可联系我们的销售团队,就具体应用作进一步讨论。

探索更多深海快换接头解决方案!

在浅海、深海和超深海域油气应用中,选择合适的液压快换接头至关重要。为了实现液压快换安全可靠的连接,密封、水深、插拔力和材料选择等诸多因素均需考虑。

- Subsea Connection Systems - Parker Hannifin

Subsea Coupling Solutions:Plate and Cartridge Mountable Stab Couplings,ROV and Diver-Mateable Connections, Related Products

Stab Style Plate Mounted Couplings

|

DSL Series couplings are designed for low separation force while under pressure. Durable PEEK or optional metal seals provide confidence for connection and disconnection at full pressure and at depths down to 3000 meters.

Features:

- Sizes 1/4 through 1-1/2 inch

- Up to 15,000 psi (1034 bar) working pressure

- Poppet valves

- Metal or PEEK primary seal, PEEK secondary seal

- Redundant sealing

- Guide sleeve option

- Welded tube stub option

Typical Applications:

- Flying lead plates

- Subsea control modules

- Subsea injection systems

- Tubing hangers |

|

DSC Series are traditional subsea couplings with PEEK seals.Redundant sealing adds a higher level of integrity to this proven design. The guide sleeve eases alignment of the coupler and nipple for a smooth connection.

Features:

- Sizes 1/4 and 1/2 inch

- Up to 15,000 psi (1034 bar) working pressure

- Poppet valves

- PEEK primary seal

- Redundant sealing

- Guide sleeve option

- Welded tube stub option

Typical Applications:

- Flying lead plates

- Subsea control modules |

|

DSE Series poppet style couplings are the most common design used in subsea applications and can be connected and disconnected at full system pressure. Typically connected and disconnected above water, their compact design is efficient and reliable.

Features:

- Sizes 1/8 through 1 inch

- Up to 10,000 psi (690 bar) working pressure

- Poppet valves

- Primary elastomer O-ring seal with back up

Typical Applications:

- Auxiliary intervention plates

- Elastomer O-ring seal is usually "make and break" topside

- Umbilical reelers |

|

DSP Series poppet style couplings are the most common design used in subsea applications and can be connected and disconnected at full system pressure. PEEK seals allow connection subsea and above water. Their compact design is efficient and reliable.

Features:

- Sizes 1/8 through 1 inch

- Up to 15,000 psi (1034 bar) working pressure

- Poppet valves

- PEEK primary seal

Typical Applications:

- Auxiliary intervention plates

- PEEK seal is suitable for topside or subsea "make and break" |

|

DST Series are unvalved, straight through couplings with unrestricted flow. Redundant interface sealing ensures reliable performance.

Features:

- Sizes 1/4, 1/2 and 3/4 inch

- Up to 8000 psi (552 bar) working pressure

- Unvalved straight through design

- O-ring/back up primary seal, secondary slipper seal

- Redundant sealing

Typical Applications:

- Connection plates where no valves are required

- Usually "make and break" topside |

|

DSB Series balanced couplings have no hydraulic separation force while under pressure. The PEEK seals are durable for connecting at full system pressure.

Features:

- Size 3/8 inch

- Up to 10,000 psi (690 bar) working pressure

- Balanced design - no separation force from pressure

- PEEK primary seal

Typical Applications:

- Subsea control modules

- Intervention systems

Stab Style Plate Mounted Couplings |

|

DSA and DSU Series poppet couplings are used in many subsea and topside applications. The ability to connect and disconnect under full system pressure, and sealing that can withstand internal and external pressure, provides secure connections for a variety of applications.

Features:

- Size 1/4 inch

- 5000 psi (345 bar) working pressure

- Poppet valves

- Back up/O-ring/back up primary seal

- Parker Nitrile O-rings standard

Typical Applications:

- Umbilical reelers

- MUX plates |

|

DSH Series couplings are used in subsea and topside RBJPlates. Typically found in hydraulic pilot applications they replace legacy couplings, pipe nipples, and fittings eliminating potential leak paths and reducing assembly time. The superior valve design of he DSH Series accomodates plate flex up to 0.100 in/2.54mm.

Features:

- Size 1/4 inch

- 6000 psi (414 bar) working pressure

- Poppet valves

- Redundant sealing

- Flow check resistant design

- Eliminates potential leak paths

- Reduces assembly time

- Parker Nitrile O-rings standard

Typical Applications:

- Umbilical reelers

- MUX plates |

|

DSF Series poppet style couplings are self-aligning allowing rigid mounting of both the male and female. High operating pressures and robust construction make them ideal for the most challenging subsea applications.

Features:

- Sizes 1/8 and 3/8 inch

- Up to 25,000 psi (1725 bar) working pressure

- Poppet valves

- PEEK primary seals

- Parker Nitrile O-rings standard

Typical Applications:

- Intervention control systems

- Subsea test trees |

|

DSM Series couplings have poppet valves and threaded sleeves. They are manually operated, diver mateable subsea connections with proven performance.

Features:

- Sizes 1/4 through 1 inch

- Up to 10,000 psi (690 bar) working pressure

- Poppet valves

- Metal primary and PEEK secondary seal

- Connect/disconnect under pressure

Typical Applications:

- Auxiliary intervention plates

- Diver mateable connections

|

|

DSS Series

Inline or Manifold Mounted Swivels

DSS Series swivels provide an unobstructed flow path force balanced design and low friction PTFE slipper seals minimize rotation torque. These features minimize pressure loss, can increase hose life and reduce fitting loosening.

Features:

- Sizes 1/2 and 1 inch

- 5000 psi (345 bar) working pressure

- Force balanced

- Full flow design

- Redundant sealing

- Low friction PTFE slipper seals

Benefits:

- Prevents hose twisting

- Reduces fitting loosening |

- Custom engineered couplings and accessories

|

Custom Engineered Products

MCD Series

ROV Mateable Stab Plates

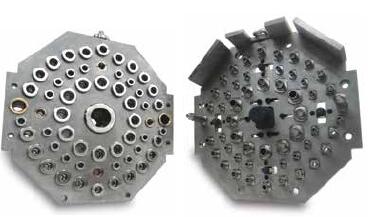

Parker's custom engineered couplings and accessories utilize proven designs to satisfy specific customer requirements and provide reliable connections that endure the demanding subsea environment.

Custom engineered solutions have included:

- Couplings mounted in ROV housing

- Cartridge mounted coupling with a self aligning nipple

- Coupling rated to 25,000 psi (1723 bar) and 160°C

- Poppet style couplings in a diver-mateable plate

- Multi-coupling plates connecting over 50 fluid lines |

|

- Related Products - Offshore Topside Couplings

Other Topside Applications

石油顶驱配套用快速接头 Top Drives

|

H & 60 Series - 316 Stainless Steel

- Corrosion resistant materials

- Quick connections allow for equipment maintenance |

|

75 Series - 316 Stainless Steel

- Durable threaded connection for large bore hoses

- Wings allow for easy operation

|

- ROV潜水器配套快速接头

|

60 Series - 316 Stainless Steel

- Proven perfomance

- ISO 7241, series B compliant |

|

71 Series - 316 Stainless Steel

- High pressure

- Flush face, low spill

|

- Other Topside Applications其他顶驱设备配套快速接头

|

1141 Series - 303 Stainless Steel & Brass

- Thread to connect

- 1/4 inch body size |

|

FS Series - 316 Stainless Steel

- Push to connect operation

- Non-spill flush valves |

|