|

|

|

|

Sour Service Check Valves

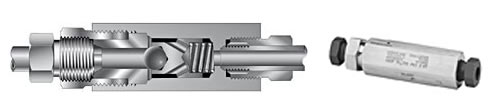

Since 1945 Autoclave Engineers has designed and built premium quality valves, fittings and tubing. Autoclave's high-pressure SOG check valves are capable of operating to 30,000 psi (2068 bar) and range in size from 1/4" to 9/16" tube size. Check valves available in O-ring, ball and ball type excess flow designs.

Sour Service Check Valves: Sour Service Products

O-Ring, Ball and Excess Flow Check Valves to 30,000 psi (2068 bar)

FEATURES

Tubing sizes are 1/4", 3/8" and 9/16".

Coned-and-threaded connection

O-ring and ball check valves

Ball type excess flow valves

Special material available.

BENEFITS

Autoclave's high-pressure check valves are used as fluid handling components in oil and gas industries where H2S is present. Autoclave type SOG Components are available with standard API Test and gauge connections (Autoclave F562C). These components provide dependable performance in gas and liquid applications

Sour Service Ball Check Valves

Prevents reverse flow where leak-tight shut-off is not mandatory . When differential drops below cracking pressure, valve closes. With all-metal components, valve can be used up to 1200°F (649°C). See Technical Information section for connection temperature limitations. (Not for use as a relief valve.)

Ball and poppet are integral design to assure positive, in-line seating without “chatter”. Poppet is designed essentially for axial flow with minimum pressure drop.

Materials: Body, cover, poppet: 316 Annealed Stainless Steel, Cover gland: Annealed Stainless Steel, Ball, Spring: High Nickel Alloy

Note: All sour oil and gas valves and fittings supplied without collars and glands unless otherwise specified.

Caution: While testing has shown O-Rings to provide satisfactory service life, both cyclic and shelf life may vary widely with differing service conditions, properties of reactants, pressure and temperature cycling and age of the O-ring. FREQUENT INSPECTIONS SHOULD BE MADE to detect any deterioration, and O-rings replaced as required.

All dimensions for reference only and subject to change.

For prompt service, Autoclave stocks select products. Consult your local representative.

All general terms and conditions of sale, including limitations of our liability, apply to all products and services sold.

| Item # |

Fits Connection Type |

Pressure Rating |

Orifice |

Rated C v |

| CB4401-SOGWO |

F250C |

30000 psi

2068.39 bar |

0.094 Inch

2.39 mm |

0.15 |

| CB6601-SOGWO |

F375C |

30000 psi

2068.39 bar |

0.125 Inch

3.18 mm |

0.28 |

| CB9901-SOGWO |

F562C |

30000 psi

2068.39 bar |

0.187 Inch

4.75 mm |

0.63 |

Provides unidirectional flow and tight shut-off for liquids and gas with high reliability. When differential drops below cracking pressure*, valve shuts off. (Not for use as relief valve.)

Materials: Body, cover, poppet: 316 Annealed Stainless Steel, Cover gland: Annealed Stainless Steel: High Nickel Alloy, Standard O-ring: Viton, for operation to 500° F (260°C). Buna-N or Teflon available for 250°F (121°C) or 400°F (204°C) respectively; specify when ordering.

*Cracking Pressure: 20 psi (1.38 bar) ±30%. Springs for higher cracking pressures (up to 100 psi (6.89bar)) available on special order for O-ring style check valves only.

Note: All sour oil and gas valves and fittings supplied without collars and glands unless otherwise specified.

Caution: While testing has shown O-Rings to provide satisfactory service life, both cyclic and shelf life may vary widely with differing service conditions, properties of reactants, pressure and temperature cycling and age of the O-ring. FREQUENT INSPECTIONS SHOULD BE MADE to detect any deterioration, and O-rings replaced as required.

All dimensions for reference only and subject to change.

For prompt service, Autoclave stocks select products. Consult your local representative.

All general terms and conditions of sale, including limitations of our liability, apply to all products and services sold.

| Item # |

Fits Connection Type |

Pressure Rating |

Orifice |

Rated C v |

| CKO4400-SOGO |

F250C |

30000 psi

2068.39 bar |

0.094 Inch

2.39 mm |

0.15 |

| CKO6600-SOGWO |

F75C |

30000 psi

2068.39 bar |

0.125 Inch

3.18 mm |

0.28 |

| CKO9900-SOGWO |

F562C |

30000 psi

2068.39 bar |

0.187 Inch

4.75 mm |

0.63 |

Sour Service Ball Type Excess Flow Valves

Protects pressure gauges and pressure instrumentation from surges in flow or sudden venting in the event of line failure.

Materials: Body, cover, sleeve: Type 316 Annealed Stainless Steel, Ball: 300 Series Annealed Stainless Steel, Cover gland: annealed stainless steel.

Vertical Installation: Since this type of check valve employs a non-spring loaded ball, valve MUST be installed in VERTICAL position with arrow on valve body pointing UP. (cover gland up).

Resetting Valve: Equalize the pressure across the ball. The ball will drop and reset automatically.

Note: All sour oil and gas valves and fittings supplied without collars and glands unless otherwise specified.

Caution: While testing has shown O-Rings to provide satisfactory service life, both cyclic and shelf life may vary widely with differing service conditions, properties of reactants, pressure and temperature cycling and age of the O-ring. FREQUENT INSPECTIONS SHOULD BE MADE to detect any deterioration, and O-rings replaced as required.

All dimensions for reference only and subject to change.

For prompt service, Autoclave stocks select products. Consult your local representative.

All general terms and conditions of sale, including limitations of our liability, apply to all products and services sold.

| Item # |

Fits Connection Type |

Pressure Rating |

Orifice |

| CK4402-SOGWO |

F250C |

30000 psi

2068.39 bar |

0.094 Inch

2.39 mm |

| CK6602-SOGWO |

F375C |

30000 psi

2068.39 bar |

0.125 Inch

3.18 mm |

| CK9902-SOGWO |

F562C |

30000 psi

2068.39 bar |

0.187 Inch

4.75 mm |

|