|

派克 E / EB系列聚乙烯仪表级管

Parker E and EB Series Polyethylene Instrument Grade Tubing

派克聚乙烯PE管由高分子量树脂制成,可提供更高的尺寸稳定性,均匀性和长期强度。Parker PE管满足食品接触应用的FDA和NSF-51要求,以及饮用水的NSF-61要求。线性低密度聚乙烯(LLDPE)管由100%纯树脂材料制成,适用于水,食品,饮料和食品级应用。该管道可用于通用仪器应用以及所有食物处理应用,除了在烹饪过程中保持食物外。黑色管EB系列包含紫外线抑制剂,建议在阳光照射的区域以及紧靠高紫外线光源的地方使用紫外线抑制剂。标准黑色未获准用于食品处理应用,但可以根据特殊要求订购NSF认证和FDA兼容的黑色。为了最大的保持力,应在该管上使用管支撑,以免发生端部载荷,振动或压力峰值。

派克 E / EB系列聚乙烯仪表级管

Parker E and EB Series Polyethylene Instrument Grade Tubing

市场

- 水市场

- 食品和饮料

- 流体处理

- 工业气动

- 化学传递

特性

- 由100%

纯树脂材料制成,具有长期强度- ASTM D-1693(10%IGEPAL)具有出色的抗应力开裂性,可最大限度地延长使用寿命

- 紫外线稳定,可减少日光下的褪色,开裂和强度损失

- 符合FDA,NSF-51食品接触应用要求和NSF-61饮用水要求

应用范围:

- 饮用水

- 饮料分配器

- 化学传递

- 低压气动装置

认证/合规性:

- 符合FDA的食品接触要求- 符合

ASTM D-1693(10%IGEPAL)的抗应力开裂性

- ASTM D-1248,I型,A级,类别4,E5级

- NSF – 51

- NSF – 61

注意:

- 符合Parker流体系统连接器部门的要求(特定配件请参阅PFD目录CAT.4660或FSC目录CAT3501E USA)

- 不透明的颜色有黑色,蓝色,灰色,绿色,橙色,紫色,红色,白色和黄色

- 黑色(EB)管道包含紫外线抑制剂,建议在日光照射区域和高紫外线光源附近使用

- 在额定压力下使用兼容的流体,建议的工作温度范围为-80°F(-62°F) C)到+ 150°F(+ 66°C)

- 该管应与管支撑一起使用,以在端部负载,振动或压力最大的情况下保持功率

- 壁厚仅供参考

性能特点

最大工作压力8.6巴

125磅/平方英寸

最小弯曲半径1-4英寸

25至101.6毫米

管内径4-13毫米

0.170-1/2英寸

管外径1 / 4、5 / 16、3 / 8、1 / 2、5 / 8英寸

6、8、10、13、16毫米

符合规格ASTM D-1693;符合FDA NSF-51;NSF-61

应用流体处理,化学传递,气动,水

颜色自然,黑色,蓝色,灰色,绿色,橙色,紫色,红色,白色,黄色

管壁厚度0.040或0.062英寸

1至1.6毫米

最小爆破压力280至580 psi

19.3至40巴

最低工作温度-80°华氏度

-62°摄氏度

最高工作温度150°华氏度

66°摄氏度

媒体空气,饮用水,水,化学药品

兼容配件Dubl-Barb?,流量控制,Prestolok,Liquifit,TrueSeal,压缩,Compress-Align?,Poly-Tite,高负荷,快速和Tite

管材聚乙烯

每包长度100、500或1000英尺

-

Product Type: Polyethylene Tubing

-

Manufacturer: Parker Parflex

-

Product Family: Series E

-

Length: 100 ft.

-

Materials: Polyethylene Tubing

-

Tubing Rating: Instrument Grade

-

Tubing Size: 1/4 in.

-

Wall Thickness: 0.040 in.

-

Working Pressure: 120 PSI @73°F

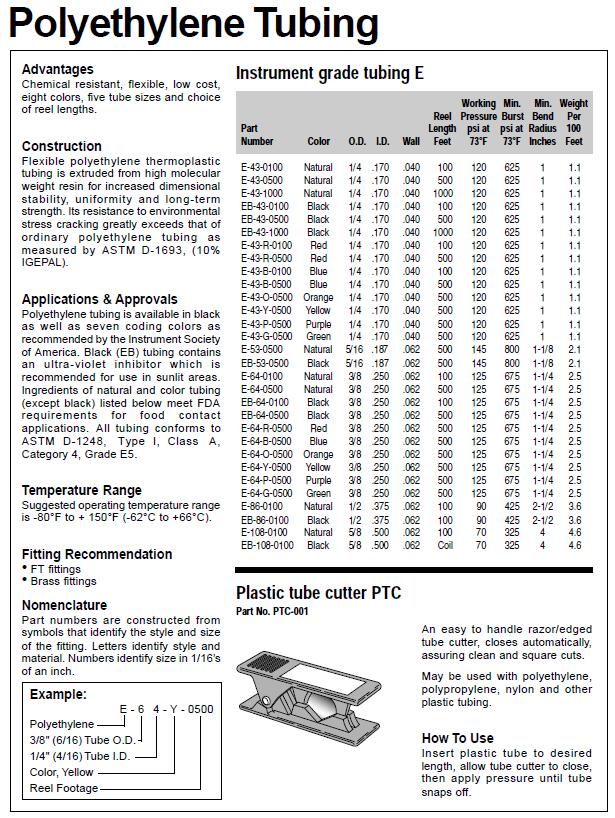

Part Length psi at psi at Radius 100 Number Color O.D. I.D. Wall Feet 73°F 73°F Inches Feet E-43-0100 Natural 1/4 .170 .040 100 120 625 1 1.1 E-43-0500 Natural 1/4 .170 .040 500 120 625 1 1.1 E-43-1000 Natural 1/4 .170 .040 1000 120 625 1 1.1 EB-43-0100 Black 1/4 .170 .040 100 120 625 1 1.1 EB-43-0500 Black 1/4 .170 .040 500 120 625 1 1.1 EB-43-1000 Black 1/4 .170 .040 1000 120 625 1 1.1 E-43-R-0100 Red 1/4 .170 .040 100 120 625 1 1.1 E-43-R-0500 Red 1/4 .170 .040 500 120 625 1 1.1 E-43-B-0100 Blue 1/4 .170 .040 100 120 625 1 1.1 E-43-B-0500 Blue 1/4 .170 .040 500 120 625 1 1.1 E-43-O-0500 Orange 1/4 .170 .040 500 120 625 1 1.1 E-43-Y-0500 Yellow 1/4 .170 .040 500 120 625 1 1.1 E-43-P-0500 Purple 1/4 .170 .040 500 120 625 1 1.1 E-43-G-0500 Green 1/4 .170 .040 500 120 625 1 1.1 E-53-0500 Natural 5/16 .187 .062 500 145 800 1-1/8 2.1 EB-53-0500 Black 5/16 .187 .062 500 145 800 1-1/8 2.1 E-64-0100 Natural 3/8 .250 .062 100 125 675 1-1/4 2.5 E-64-0500 Natural 3/8 .250 .062 500 125 675 1-1/4 2.5 EB-64-0100 Black 3/8 .250 .062 100 125 675 1-1/4 2.5 EB-64-0500 Black 3/8 .250 .062 500 125 675 1-1/4 2.5 E-64-R-0500 Red 3/8 .250 .062 500 125 675 1-1/4 2.5 E-64-B-0500 Blue 3/8 .250 .062 500 125 675 1-1/4 2.5 E-64-O-0500 Orange 3/8 .250 .062 500 125 675 1-1/4 2.5 E-64-Y-0500 Yellow 3/8 .250 .062 500 125 675 1-1/4 2.5 E-64-P-0500 Purple 3/8 .250 .062 500 125 675 1-1/4 2.5 E-64-G-0500 Green 3/8 .250 .062 500 125 675 1-1/4 2.5 E-86-0100 Natural 1/2 .375 .062 100 90 425 2-1/2 3.6 EB-86-0100 Black 1/2 .375 .062 100 90 425 2-1/2 3.6 E-108-0100 Natural 5/8 .500 .062 100 70 325 4 4.6 EB-108-0100 Black 5/8 .500 .062 Coil 70 325 4 4.6

Linear Low Density Polyethylene (LLDPE) tubing is made from 100% virgin resin material for water, food, beverages and food grade applications.

Parker polyethylene (PE) tubing is produced from a high molecular weight resin to provide increased dimensional stability, uniformity and long-term strength. Parker PE tubing meets the FDA and NSF-51 requirements for food contact applications and NSF-61 for potable water.

The tubing may be used in general-purpose instrument applications as well as all food handling applications except holding food during cooking. The black tubing, EB series, contains an ultraviolet inhibitor which is recommended for use in sunlit areas and in close proximity to high, ultraviolet light sources.

Standard black is not approved for food handling applications, but NSF-listed and FDA-compliant black can be ordered on special request. A tube support should be used with this tubing for maximum holding power where end loading, vibration or pressure spikes may occur.

Markets

- Water Market

- Food & Beverage

- Fluid Handling

- Industrial Pneumatics

- Chemical transfer

Features

- Made from 100% virgin resin material for long term strength

- ASTM D-1693 (10% IGEPAL) For excellent stress crack resistance maximizes the service life

- UV stabilized to reduce fading, cracking and loss of strength from sunlight

- Meets FDA, NSF-51 requirements for food contact applications and NSF-61 for potable water

Applications:

- Potable water

- Beverage dispensers

- Chemical transfer

- Low pressure pneumatics

Certifications/Compliance:

- FDA compliant for food contact

- ASTM D-1693 (10% IGEPAL) for stress crack resistance

- ASTM D-1248, Type I, Class A, Category 4, Grade E5

- NSF – 51

- NSF – 61

Notes:

- Qualified with Parker Fluid System Connectors Division (See PFD Catalog CAT. 4660 or FSC Catalog CAT3501E USA for specific fittings)

- Opaque colors are available in black, blue, gray, green, orange, purple, red, white and yellow

- Black (EB) tubing contains an ultraviolet inhibitor which is recommended for use in sunlit areas and in close proximity to high ultraviolet light source

- The recommended operating temperature range for service at rated pressures with compatible fluids is -80°F (-62°C) to +150°F (+66°C)

- A tube support should be used with this tubing for maximum holding power where end loading, vibration or pressure

- Wall thickness is for reference only

-

Products

- Aerospace Systems and Technologies

- Air Preparation (FRL) and Dryers

- Cylinders and Actuators

- EMI Shielding

- Filters, Separators and Purifiers

- Fittings and Quick Couplings

- Gas Generators

- Hose, Piping, Tubing and T-Slot Framing

- Medical and Dental Equipment

- Motors, Drives and Controllers

- Power Take Offs and Drive Systems

- Pumps

- Refrigeration and Air Conditioning

- Regulators, Monitoring, Sensors and Flow Control

- Seals and O-Rings

- Thermal and Power Management

- Valves

Parker Hannifin

|