|

|

|

|

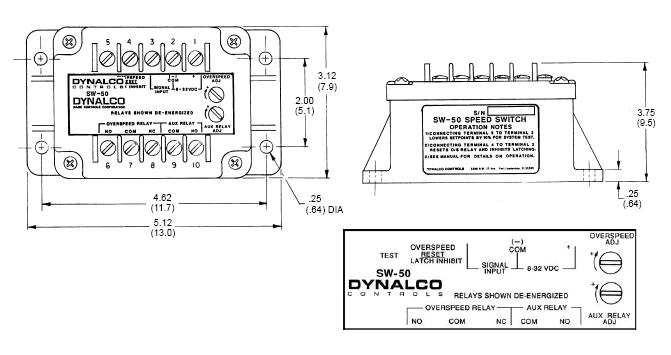

SW-50 Speed Switch发动机超速保护开关

Speed Switch and Speed Transmitter from Dynalco Controls

SW-50提供可靠的发动机超速保护,完全可现场编程。它有两个继电器设定值:一个超速加一个用于曲柄断开、发电机磁场闪烁或其他报警的辅助。SW-50 provides reliable engine overspeed protection and is fully field- programmable. It has two relay setpoints: one overspeed plus one auxiliary for crank disconnect, generator field-flashing, or other alarm.

SW-50 Speed Switch

Download Info:

SW-50 Data Sheet

SW-50 Manual

Product Code: SW-50

SW-50

Two-Setpoint

Speed Switch

Product Data Sheet

March 2009 Instrumentation & Controls

2-Year

Warranty

Reliable engine overspeed protection.

Overspeed relay plus a second setpoint for

crank disconnect, generator field- flashing,

or other alarm. Full field-programming

capability.

FEATURES

?? Various signal sources: Senses signal

frequency from magnetic pickup or AC signal

generator.

?? Field-programmable: Two 25-turn trim

potentiometers provide adjustment for setpoints

over 3–100% of full-scale frequency range.

?? Test circuit: Permits on-line testing without

overspeeding the protected device.

?? Rugged: Sealed, gasketed, reinforced case.

ENVIRONMENTAL

Temperature (storage & operation): -40oC to

+85oC (–40oF to +185oF).

Vibration:

a. MIL STD 810C, Method 514.2, Curve P,

Procedure V.

b. MIL STD 202F, Method 201A (10–55Hz,

continuous displacement of 0.06 inches P-P).

Screws on all access holes are predrilled for

safety wire.

Humidity: SAE J1211, paragraph 4.2.3., fig. 3A

(95% relative humidity at +66oC (+150oF).

Dust: MIL STD 810C, Method 510.1, Procedure 1,

Steps 1, 4, 5, and 6. (1750 ft/min velocity; 0.3g/ft3

density; <176 microM average particle size).

Sealing: Case can easily be opened and resealed

without damaging watertight integrity. O-ring sealed

access holes for setpoint adjustments. Complies

with NEMA Standard 250, types 4, 12, and 13.

Moisture protection: Component board entirely dipcoated

with moisture-repellent sealant.

SPECIFICATIONS

Input signal: Two input frequency ranges:

0–5,000 Hz, standard; or 0–10,000 Hz. Minimum

signal requirement: 0.15 Vrms (150 mVrms) for all

frequencies. Maximum signal: 70 Vrms. Minimum

input resistance: 10 KΩ.

Input power: 8–32 Vdc. (Operates with 12 or 24 Vdc

systems.) Maximum current consump-tion: 95 mA.

Can withstand 800 volts peak reverse; 80 volts peak

forward for 0.1 second maximum duration; and 350

volts peak forward for 1 millisecond duration.

Relays: SPDT for Overspeed; SPST N.O. contacts

for Auxiliary relay. Contact rating of 5 amperes at 30

Vdc/300 Vac, resistive. Setpoint adjustment range for

both relays: 3–100% of full-scale frequency range.

Integral 25-turn trim potentiometer for each relay

setpoint. Response time for both relay setpoints is 50

milliseconds, maximum.

Toll Free 800.368.6666 (US & Canada) ? Tech Support 800.950.2382

Main 954.739.4300 ? Fax 954.484.3376 ? www.dynalco.com

A division of Crane Co. 3690 NW 53rd Street, Ft. Lauderdale, FL 33309 USA

SPECIFICATIONS (cont'd)

At stand-still (zero speed), power on, the standard

relay configuration is:

1. Overspeed relay: SPDT, normally energized.

Relay de-energizes and latches on overspeed.

Latching may be inhibited by jumpering Terminal 4 to

Terminal 2; resetting is then automatic.

2. Auxiliary relay: Normally de-energized. Relay

energizes above the setpoint, non-latching (automatic

reset).

Resetting relays:

a. The latched Overspeed relay is reset (after

speed is reduced by at least 2% below setpoint

value) by momentarily jumpering Terminal 4 to

Terminal 2 or by momentarily removing power.

b. The Auxiliary relay will automatically reset when

speed is reduced by at least 2% below setpoint

value.

Power up considerations: No relay flicker on power

up. At stand-still or speeds below setpoints, applying

dc power causes no flicker or change in the normally

de-energized Auxiliary relay. Power application resets

the Overspeed relay to the normally energized (no

alarm) condition.

Grounding, phase referencing: All circuits are

isolated from earth ground. The input circuit is

referenced to the negative side of the power supply so

that the magnetic pickup can be paralleled with

electrical governors and other similarly constructed

devices.

Signal cable shield: can be grounded directly or

taken to any designated electrical terminal on the

governor. (No shield terminal is provided in the speed

switch.)

Test: Jumpering Terminal 5 to Terminal 2 lowers the

setpoints to 90% ±2% of the actual value to permit

verifying the alarm setpoints without overspeeding

the engine.

Stability of setpoints:

a. Signal amplitude effect: ±0.5% full- scale

from 150 mVrms to 100 Vrms.

b. Power supply voltage effect: ±0.1% of

full-scale with 25% supply fluctuation.

c. Temperature effect: ±2.5% of full-scale

maximum with change in enviromental

temperature from –40oC to +85oC (–40oF to

+185oF).

Hysteresis: 2% of full-scale frequency, nominal.

|