|

|

|

|

Parker Fittings接头

Tube Fabrication Equipment

Combination Inspection Gauge

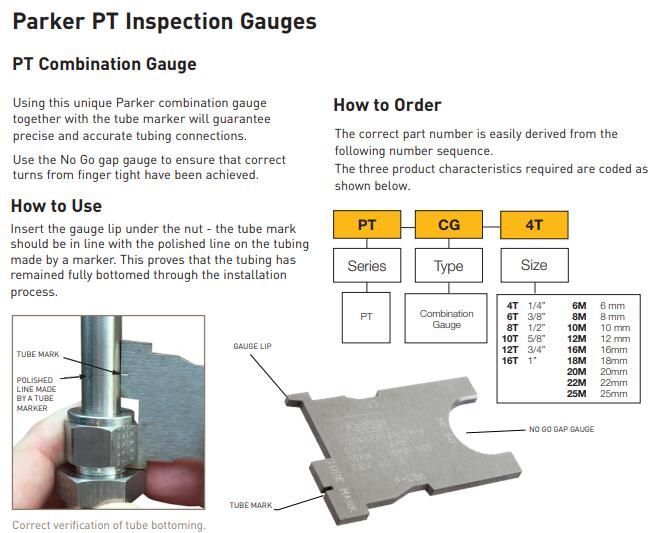

This unique to Parker Go / No Go gauge has dual purpose. Use the Go/No Go portion (on one end) to check the tube insertion depth. Use the other end to check the space between the nut and body hex.

In all industrial processes it is important to ensure that equipment is properly installed and maintained to avoid unplanned stoppages. Often, it is the simplest of oversites that can result in expensive downtime, although there are more serious consequences associated with failure such as blow outs, which have the potential to compromise the safety of the workforce. From our extensive experience in the field we know that non-bottomed tubing is a major factor that can result in leakage and potentially failure of a fitting. This can cause a real safety issue as there is the danger that the tubing can blow out, releasing high pressure hot or caustic process fluid into the immediate environment. It was because of this that we developed a gauge that would give engineers a visual indication of whether the tubing had been correctly installed.

Combination Inspection Gauge

The go / no go gauge gauge is simple to use – it is safe and reliable – but, more importantly, it ensures that installation is right first time, every time. It allows the end user to check that the correct turns of the nut are made and can also ensure that the tube is fully bottomed within the fitting. It does this through the use of a depth marker which makes a polished line on the tubing. Once the nut has been tightened 1 ? turns from finger tight, the line will be visible above the nut.

The go / no go gauge gauge not only allows the end user to check that the correct turns of the nut have been made, ensuring that it is not under or over-tightened, but also ensures that the tube is properly bottomed in the fitting. All the user needs to do is insert the gauge lip under the nut and the tube mark should be in line with the polished line. This proves that the tubing has remained fully bottomed through the installation process. Simple and effective, go / no go gauge gauges such as this ensure the safety of personnel working in the immediate vicinity of the process, whilst avoiding unnecessary downtime and lost production through failure or leakage of the connection. Parker go / no go gauge gauges are definitely worth considering if you are looking for a tube fitting solution that offers greater safety and security, whilst extending Mean Time Before Failure (MBTF).

The gauge is available in 1/4", 3/8", 1/2", 3/4" and 1" imperial sizes, and in 6 mm, 10 mm, 12 mm, 18 mm and 25 mm metric sizes.

Markets:

- Oil and Gas Offshore

- Oil and Gas Onshore

- Petrochemical

- Chemical

Features/Benefits:

- Go / No go gap gauge

- Prevents incorrect assembly

Applications:

- Instrumentation tube fitting assembly

Compatible Products

- A-LOK double ferrule compression fittings

- Instrumentation grade tube

Technical Specifications

Industry Application: |

Instrumentation Fitting Assembly |

| Materials of Construction: |

Aluminium |

Combination Inspection Gauge 型号

|