无油流报警开关Digital No-Flow Timer 无油流报警开关Digital No-Flow Timer

The Revolutionary Digital No-Flow Timer for Compressor Lube Systems

DNFT performs monitoring and shutdown functions like No-Flow, Low-Flow or Excessive-Flow for Divider-Block Lubrication Systems. The DNFT is a totally enclosed solid state electronic device for detecting Slow-Flow and No-Flow on in-line progressive lubrication systems. The Digital No-Flow Timer incorporates a crystal oscillator to accurately monitor the cycle time of the lubrication system enabling precision timed shutdown capability. An internal Lithium battery powers it, which is easily replaceable.

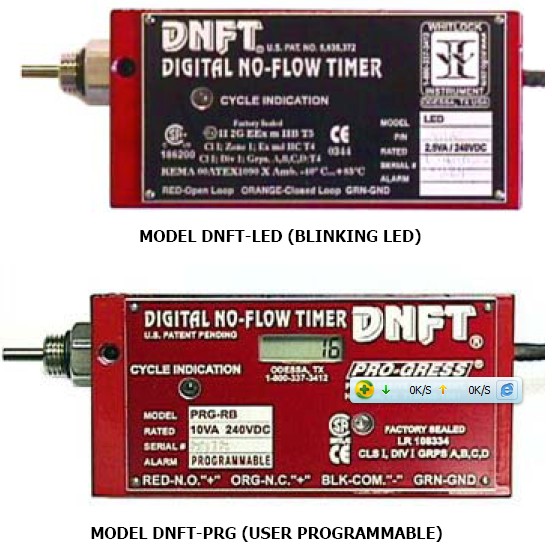

The DNFTs come in three models to switch voltages up to 240 VDC:

LED model

LCC model

PRG model

产品选型资料下载:

· DNFT-PRG

· DNFT-LCC

· DNFT-LED

· DNFT-LED-PS

· DNFT-PRG-PS (Programmable)

· DNFT-PRG (Standard, Programmable)

DNFT-PRG-PS (Programmable w/ PS Option)

DNFT-LCC 45 Second Alarm

DNFT-LCC 2 Minute Alarm

DNFT-LCC 3 Minute Alarm

DNFT-LCC 4 Minute 15 Second Alarm

DNFT-LED

DNFT-LED-PS

Digital No-Flow Timer (DNFT)

Premier Digital No-Flow Timer (DNFT)无油流开关产品介绍: Monitors Movement of Divider Valve Piston

监测分配器柱塞的运动

Closed Loop or Open Loop Operation

开式或闭式回路 Installs Directly to Divider Valve

直接安装在分配器上面

Not Affected By Temperature or Viscosity

不受温度和粘度的影响

Requires No External Power

不需要外接电源

LED or LCC Cycle Indicator

带LED或LCC循环指示

Dependable “Timed” Shutdown Protection

可靠的停机保护

Explosion Proof Rated for

防爆等级:

Class 1, Division 1, Groups A,B,C,D

CSA Approved

通过CSA防爆认证 CE Approved 和CE防爆认证

SPECIFICATIONS :

Material..................................................Stainless Steel, Aluminum

Temperature Range............................................. -40 F to +185 F

Switch Rating..........................................................2.5VA/240 VDC

Epoxy Encapsulated............................UL LISTED EL-CAST VFR 641

Alarm/Shutdown......................... Factory default for 2 minute alarm

Power.......................................Field Replaceable -Lithium Battery

Battery....................................................................... P/N 000505

Alternate Battery..........................................Radio Shack 960-0418

Divider Block Application...............Dropsa/Lincoln/SBCO/Lubriquip

Warranty...........................................................................2.5 Years

WHITLOCK

DIGITAL NO-FLOW TIMER

506LIT LED-WI-1

DNFT

WHITLOCK INSTRUMENT

07.11.01

1300 N. Texas Odessa, TX 79761

R

915.3373412 Fax 915.335.5926

DIGITAL NO-FLOW TIMER

1.800.337.3412 www.noflo.com INSTRUMENT

U.S. PAT. NO. 5,835,372 WHITLOCK

ODESSA, TX USA

DNFT-LED

P/N: 000506

MODEL Factory Sealed RATED 2.5VA / 240VDC

R

II 2G EEx m IIB T5 CE SERIAL #

C US ClI;Zone1;ExmdIICT4 000506

ClI;Div1;Grps.A,B,C,D;T4 ALARM 2-MIN

186200 0344 P/N

KEMA 00ATEX1090 X Amb. -40° C...+85°C

RED-Open Loop ORANGE-Closed Loop GRN-Ground

DNFT-LED

MONITORS MOVEMENT OF DIVIDER

VALVE PISTON FOR DEPENDABLE

"TIMED" SHUTDOWN PROTECTION

CLOSED LOOP OR OPEN LOOP OPERATION INSTALLS DIRECTLY TO DIVIDER VALVE

NOT AFFECTED BY TEMPERATUREOR OIL VISCOSITY

REQUIRES NO EXTERNAL POWER

LED INDICATOR -CYCLE INDICATION

DEDICATED SWITCH CLOSURE TO MONITOR EACH DIVIDER VALVE CYCLE (PS OPTION)

FIELD REPLACEABLE BATTERY

186200 Cl I; Div 1; Grps. A,B,C,D;T4

KEMA

00ATEX1090

X

Amb.

-40°

C...+85°C

DESCRIPTION

The DNFT-LED is a totally enclosed electronic device, combining the latest technology in microprocessor and transistor components for detecting Slow-Flow and No-Flow of divider block lubrication systems. The DNFT incorporates an oscillating crystal to accurately monitor the cycle time of the lubrication system to enable precision timed shutdown capability. The magnet assembly and control housing mount directly to the divider valve to become an integral part of the lubrication system. The DNFT operates on a field replaceable lithium battery. If battery voltage drops below normal operating levels, the DNFT goes into alarm mode and the unit cannot be restarted. LED models utilize an LED to indicate each cycle of the divider valve. This enables the operator to easily set and monitor lubrication rates.

OPERATION

Lubricant flow through the divider valve assembly forces the pistons to cycle back and forth causing a lateral movement of a magnet linked to the piston. Movement is monitored by the microprocessor which resets the timer, lights the LED, and allows the unit to continue operation, this indicates one complete cycle of the lubrication system. The microprocessor must receive this cycle in a predetermined time or a shutdown will occur. The DNFT will automatically reset alarm circuit when normal operation of divider valve resumes.

WHITLOCK

506LIT LED-WI-2

DNFT WHITLOCK INSTRUMENT

DIGITAL NO-FLOW TIMER

INSTRUMENT

P/N 000506 DNFT-TO-LED DIGITAL NO-FLOW TIMER INSTALLS ON DROPSA/LINCOLN/SBCO/LUBRIQUIP DIVIDER

BLOCK. SWITCH RATING 2.5VA 240VDC

1.

Loosen all Allen head set screws (A) on DNFT (B) and remove magnet housing (C). Do not remove magnet, spring or spacer from magnet housing.

2.

Remove piston enclosure plug (D) from end of divider valve where DNFT will be installed. The DNFT does not have to be installed on the top divider valve. It may be installed on any convenient divider valve, top to bottom. (Notice:Do not install DNFT on Lincoln divider valves with cycle indicator pins or any Dropsa divider valve less than SMX 16.)

3.

Be sure O-ring or metal gasket (F) is in place on magnet housing (C). Screw magnet housing (C) into end of divider valve (E). Torque to 15 foot pounds max.

4.

Slide DNFT (B) all the way onto hex of magnet housing (C). Tighten set screws on hex of magnet housing. Torque 25 inch pounds max.

5.

The LED on the DNFT indicates each divider valve cycle. This enables operator to adjust the lubricator pump for correct cycle time and oil consumption recommended by compressor manufacturer. If LED does not blink with compressor running or by manually pumping oil into divider valve, the DNFT must be adjusted. Normal cycle indication is a bright strobe type blink.

6.

Before adjusting DNFT, divider valve must be cycling. This can be achieved with the compressor running or by manually pumping oil through the divider valve assembly with a hand priming pump.

7.

Adjustment is made by sliding the DNFT (B) all the way on the hex of the magnet housing (C). Tighten set screws on hex of the magnet housing to 25 inch pounds max. Check for LED blink to confirm correct adjustment. If LED does not blink with divider valve cycling, adjust the DNFT back in 1/16" increments. Correct adjustment of the DNFT is confirmed by blinking LED.

8.

All conduit and connections should be appropriate for area classification. Notice: Conduit and fittings must be supported to avoid bending magnet housing.

9. After installing magnet assembly and pre-compressor start-up, it is absolutely necessary to purge all air from dividerblock lubrication system. This can easily be accomplished with a lubrication system purge gun.

10.DNFT must be installed with correct magnet assembly for each divider valve manufacturer.

Lincoln-7/16"-20 extended nose with O- ring Dropsa

Trabon-1994 or earlier 7/16"-20 with metal crush gasket SBCO &Trabon-1995 and later 7/16"-20 with O-ring

Notice: When installing more than one DNFT, each DNFT must be wired to a separate alarm circuit of the control panel, annunciator or PLC to simplify troubleshooting the lubrication system and DNFT.

O-RING OR ALLEN HEAD

INTERNALVIEWOF DIVIDERVALVE METAL GASKET (F) DNFT (B) MAGNET HOUSING SPACER SET SCREWS(2) (A) SPRING #22AWG18"LEADS(7)(I)

(E) (C)

WHITLOCK

RED

DIGITALNO-FLOWTIMER

RED GREEN

INSTRUMENT

GREEN

ORANGE

ORANGE

CYCLEINDICATIONODESSA,TXUSA

MODEL LED

ORANGE

RATED 2.5VA / 240VDC

ORANGE

24S

Factory Sealed

R

C US

LED

CE

II2GEExmIIBT5

SERIAL#

000506

ClI;Zone1;ExmdIICT4

0344

P/N

186200

ClI;Div1;Grps.A,B,C,D;T4

2-MIN

ALARM

MAGNET FIELD REPLACEABLE

KEMA00ATEX1090XAmb.-40°C...+85°C

RED-OpenLoopORANGE-ClosedLoopGRN-Ground

BATTERY

(H)

P/N:000505

DNFT-LED

O-RING

24S

PISTONENCLOSUREPLUG (F)

(D) 1/2“PIPEPLUG CONTROL HOUSING POLARIZEDCONNECTOR

CAUTION: DISCONNECT ALL WIRING PRIOR TO WELDING ON COMPRESSOR OR SKID.

WIRING LEGEND

RED..................NORMALLY OPEN OPERATION ORANGE..........NORMALLY CLOSED OPERATION GREEN.............CASE GROUND UNIT MUST BE SECURELY GROUNDED. DISCONNECT ALLWIRING PRIOR TO WELDING ON SKID.

CLOSED LOOP MODE

RED INSULATE CONTROL PANEL FROM CONTACT ANNUNCIATOR

OR PLC

ORANGE

ORANGE

GREEN GROUND

000506

NOTE: WIRING CONNECTION FOR UNIT IN OPERATION

DNFT-LED

000506

OPEN LOOP MODE

RED

CONTROL PANEL RED ANNUNCIATOR OR PLC

ORANGE INSULATE FROM CONTACT

GREEN GROUND

000506

NOTE: WIRING CONNECTION FOR UNIT IN OPERATION

WHITLOCK

506LIT LED-WI-3

DNFT

WHITLOCK INSTRUMENT

06.05.01

TROUBLESHOOTINGDNFT-LED

NOTICE: WHEN MORE THAN ONE DNFT IS INSTALLED ON THE COMPRESSOR OR ENGINE, EACH DNFT MUST BE WIRED TO A SEPARATE ALARM

CIRCUIT ON THE CONTROL PANEL, ANNUNCIATOR OR PLC TO SIMPLIFY TROUBLESHOOTING THE LUBRICATION SYSTEM AND DNFT.

PROBLEM POSSIBLE CAUSE

1. LED does Not

Blink, ControlA. Improperly AdjustedPanel IndicatesDNFT Lube No-Flow (See also, 3.Erratic shutdown)

SPRING

MAGNET SPACER B. Spring or Magnet isBroken in MagnetAssembly

MAGNETHOUSING(HEX)

STRAIGHT OK !

2. After installation of DNFT, Rupture Disc isBlown and Divider Valve is Locked up.

PISTON

ENCLOSURE

PLUGS

C. Low Battery voltage

D. Bent Magnet Housing

BENT REPLACE !

A.Wrong Magnet Housing. Installed on Divider Valve (See magnet assy. Below)

B. Air or Debris in Divider Valve System.

OUTLET PLUGS

ELETRICAL TESTING OF DNFT ALARM CIRCUIT

Faulty Lube Pump

SERVICE PROCEDURE AND / OR CORRECTION

Loosen set screws, slide DNFT all the way onto hex of magnet housing and torque to 25 inch pounds max.(Do not over tighten) Cycle divider valve by pumping clean oil through system with lubrication system purge gun or running compressor. If necessary, adjust DNFT 1/16“ back until LED blinks with each cycle of divider valve.

Loosen set screws, remove DNFT from magnet housing. Remove magnet assembly from divider valve. Remove magnet, spacer and spring. Check components for damage. Replace damaged spring and/or magnet and install on divider valve. If necessary, adjust DNFT, check for LED blink. Purge air from system with lubrication system purge gun.

Remove the battery from the DNFT per the attached instructions. Replace the battery if the voltage is below 2.5 volts using a factory recommended replacement battery.

Loosen set screws, remove DNFT from magnet housing. Check for damaged or bent magnet housing. Remove magnet assembly from divider valve. Replace magnet housing, magnet, spring and spacer. Re-install DNFT on magnet housing. If necessary, adjust DNFT, check for LED blink. Purge air from system with lubrication system purge gun.

Loosen set screws and remove DNFT from magnet housing. Check for correct magnet housing for divider valve manufacturer. Remove and replace with correct magnet housing. Replace DNFT on magnet housing. If necessary adjust DNFT, check for LED blink. Purge air from system with lubrication system purge gun.

Check system pressure insure oil is flowing to divider valves. If necessary install pressure gauge to monitor operation of lubrication system.

1. Loosen outlet plugs in front of valve blocks. Fast purge the system with lubrication system purge gun until clean, clear, air free oil appears from plugs.

2. Loosen each piston enclosure plug individually to purge air from behind piston. Do not remove piston enclosure plugs. Tighten all divider valve plugs. Adjust DNFT. To insure proper operation of the divider block lubricationsystem, it is absolutely necessary that all tubing and components be filledwith oil and free of air before start-up.

1.

NORMALLY OPEN - Attach ohmmeter to red wires. Meter should read 10 megaohms in operation and less than 10 ohms in alarm state.

2.

NORMALLY CLOSED - Attach ohmmeter to orange wires. Meter should read less than 10 ohms in operation and infinity in alarm state.

Check system pressure to insure oil is flowing to divider valves. If necessary, install pressure gauge to monitor operation of lubrication system. Check gauge to insure pump will build sufficient pressure to inject oil into cylinder. You cannot check for oil flow into cylinder by removing tubing from check valve and pumping oil to atmosphere. Replace pump.

TYPICAL Magnet Assemblies and Applications DNFT must be installed with correct magne

DNFTINSTALLATION assembly for each divider valve manufacturer.

O-RING OR

METAL GASKET SBCO &TRABON Magnet Assy # 000004 INTERNALVIEWOF O-Ring Seal DIVIDERVALVE

7/16"-20

WHITLOCK

RED

RED Trabon Metal Gasket Seal

U.S.PAT.NO.5,835,372

Magnet Assy # 000011

R

DIGITALNO-FLOWTIMER

1994 or Earlier

ORANGE

INSTRUMENT

ODESSA,TXUSA

MODEL LED

ORANGE 7/16"-20

GREEN

CYCLEINDICATION

RATED 2.5VA / 240VDC

Factory Sealed

R

II2GEExmIIBT5 SERIAL#

24S

C US ClI;Zone1;ExmdIICT4 CE P/N 000506

ClI;Div1;Grps.A,B,C,D;T4 ALARM 2-MIN

186200 0344

Lincoln O-Ring SealExtended Nose

Magnet Assy # 000012

KEMA00ATEX1090XAmb.-40°C...+85°C

RED-OpenLoopORANGE-ClosedLoopGRN-Ground

24S DNFT-LED7/16"-20

PISTONENCLOSUREPLUG DIVIDERVALVE Dropsa No Gasket Magnet Assy # 000013 CAUTION: DISCONNECT ALL WIRING PRIOR TO WELDING ON COMPRESSOR OR SKID. Raised Shoulder

WHITLOCK INSTRUMENT

506LIT LED-WI-4

DIGITAL NO-FLOW TIMER

U.S. PAT. NO. 5,835,372

1.800.337.3412 www.noflo.com

DNFT BATTERY REPLACEMENT INSTRUCTIONS

ALLEN HEAD MAGNET SET SCREWS(2) #22 AWG 18" LEADS (7)

Directions for replacing the battery in the Digital No Flow Timer.

1.

Shut down the engine or set the bypass timer.

2.

Use a 3/8" ratchet to remove the 1/2" NPT Pipe plug.

3.

Remove the battery from the DNFT and disconnect from the polarized connector.

4.

Connect the new battery to the attached polarized plug.

5.

Reinsert the battery and reinstall 1/2" NPT Pipe plug.

6.

Verify the DNFT is working by pre-lubing the system and check for LED blink.

ITEMS REQUIRED FOR REPLACING THE DNFT BATTERY:

(1)

P/N: 000505 BATTERY or RADIO SHACK P/N: 960-0418 (alternate replacement)

(1)

3/8“ RATCHET WRENCH (for removal of battery plug) |