|

耐化学腐蚀的PTFE光滑管软管-919 / 919B / 919J / 919U

Chemical Resistant PTFE Smoothbore Hose - 919/919B/919J/919U

PTFE软管具有出色的化学相容性,耐湿性,可在较宽的温度范围内使用,并且摩擦系数低,有助于流动。大多数919软管可承受的温度高达450°F。派克的耐化学腐蚀PTFE光滑管软管具有出色的化学兼容性,可承受高达+ 450°F的温度。919 / 919B组件可用于多种应用,包括但不限于化学传输线,高温通用液压系统和冷却剂线。PTFE芯管具有防潮功能,并且具有任何已知塑料中低的摩擦系数,因此可将压降和沉积物降至低。PTFE软管比金属软管更不容易因应力或弯曲而破裂。919软管符合SAE 100R14A,并由符合FDA的天然PTFE管制成,而919B软管符合SAE 100R14B,并由黑色的耗散PTFE芯管制成。输送油,油漆,燃料或蒸汽等非导电流体时,应使用Parker 919B。派克(Parker)的919J PTFE软管具有挤出的硅树脂护套,可提供清洁,光滑的覆盖层,而919U则具有无磨损,耐磨的聚氨酯护套,可保护不锈钢钢丝增强材料免受磨损,磨损和污染。这两种软管均由符合FDA标准的天然PTFE芯管制成,并由304不锈钢编织层加固。919U软管上的聚氨酯护套减小了低和高温度范围(-40°F至+ 275°F)。919J PTFE软管上的硅胶套只会降低较低的工作温度(-40°F至+ 450°F)。这两种软管均由符合FDA标准的天然PTFE芯管制成,并由304不锈钢编织层加固。919U软管上的聚氨酯护套减小了低和高温度范围(-40°F至+ 275°F)。919J PTFE软管上的硅胶套只会降低较低的工作温度(-40°F至+ 450°F)。这两种软管均由符合FDA标准的天然PTFE芯管制成,并由304不锈钢编织层加固。919U软管上的聚氨酯护套减小了低和高温度范围(-40°F至+ 275°F)。919J PTFE软管上的硅胶套只会降低较低的工作温度(-40°F至+ 450°F)。

Chemical Resistant PTFE Smoothbore Hose - 919/919B/919J/919U

pdf catalog download

Parker's Chemical Resistant PTFE Smoothbore hoses have exceptional chemical compatibility and handle temperatures as high as +450°F. 919/919B assemblies are used in numerous applications including, but not limited to, chemical transfer lines, high temperature general hydraulics, and coolant lines. The PTFE core tube resists moisture and offers the lowest coefficient of friction of any known plastic, therefore minimizing pressure drops and deposits. PTFE hoses are less susceptible to cracking from stress or flexing than metal hoses. The 919 hose meets SAE 100R14A and is constructed of a natural FDA compliant PTFE tube while 919B hose meets SAE 100R14B and is manufactured with a black static-dissipating PTFE core tube. Parker 919B should be used when conveying non-conducting fluids such as oils, paints, fuels, or steam. Parker’s 919J PTFE Hose features an extruded silicone jacket to provide a clean, smooth cover and 919U features a non-marring, abrasion-resistant polyurethane jacket to shield the stainless steel wire reinforcement against wear, fraying and contaminants. Both of these hoses are constructed of a natural FDA compliant PTFE core tube and reinforced with a 304 stainless steel braid. The polyurethane jacket on the 919U hoses reduces the minimum and maximum temperature range (-40°F to +275°F). The silicone jacket on the 919J PTFE hose only reduces the lower operating temperature (-40°F to +450°).

市场:

- 流体处理

- 医疗

- 油田服务

- 运输

- 军事

- 压缩气体

特性/优点:

- 出色的化学相容性,可在管道之间成功进行化学转移

- 处理极端温度从-100°F到+ 450°F

- 防潮

- 低摩擦力使压降和沉积物小化

- 蒸汽可清洗

- 硅胶套提供了清洁,非-耐磨的聚氨酯涂层可保护不锈钢线材免受磨损,磨损和污染

应用范围:

- 化学品输送线

- 通用液压

- 压缩空气/气体

- 胶粘剂分配

- 冷却剂线

- 医用气体

认证/合规性:

- 达到/超过SAE 100R14A-919 / 919J

- 达到/超过SAE 100R14B-919B

- 达到/超过SAE 100R14A,但温度范围为-40°F到+ 275°F-919U

- FDA CFR 177.1550 (天然管)

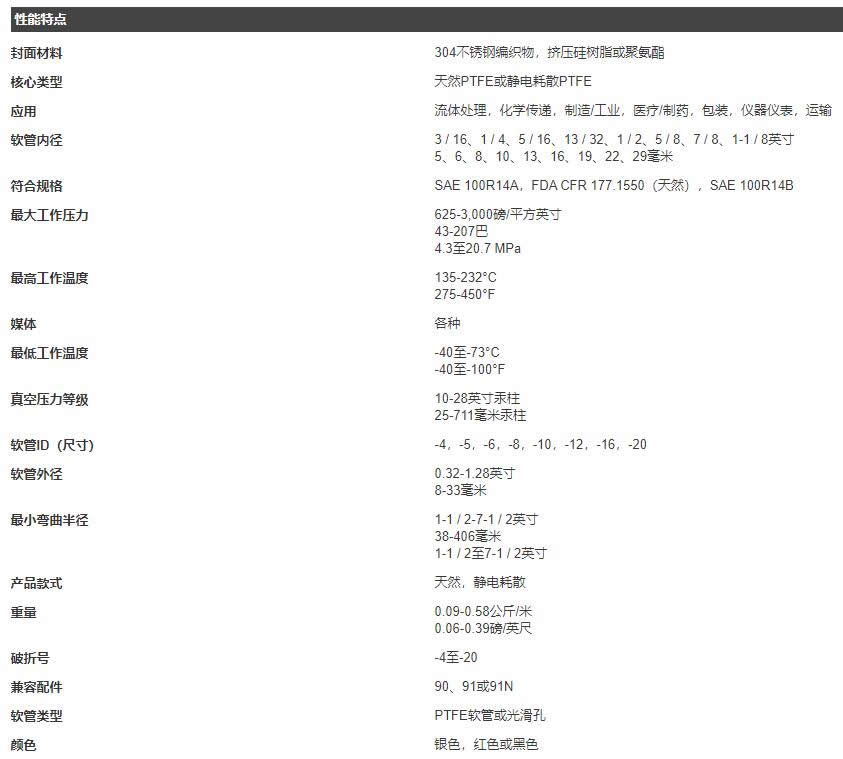

技术规格:

- 软管:919 / 919J / 919U-符合FDA的天然FDA PTFE 919B-黑色防静电PTFE

- 增强材料:304不锈钢编织物

- 输送非导电性液体(如油)时,请使用带有防静电芯管的919B型软管,油漆,燃料,蒸汽等。

- 爆裂压力是23°C(73°F)下的大工作压力的4倍

- 使用91N系列配件

- 软管内径是标称的

- 软管外径是大的

- 919J盖:挤压硅胶

- 919U盖:聚氨酯

- 盖上附件之前必须先将其刮掉

- 根据要求提供其他颜色

部件 |

软管类型 |

尺寸 |

长度 |

919-10 |

SS Braid, Natural |

-10 |

Random |

919-10-50 |

SS Braid, Natural |

-10 |

50 ft |

919-12 |

SS Braid, Natural |

-12 |

Random |

919-12-50 |

SS Braid, Natural |

-12 |

50 ft |

919-16 |

SS Braid, Natural |

-16 |

Random |

919-16-50 |

SS Braid, Natural |

-16 |

Random |

919-20 |

SS Braid, Natural |

-20 |

Random |

919-3 |

SS Braid, Natural |

-3 |

Random |

919-4 |

SS Braid, Natural |

-4 |

Random |

919-4-100 |

SS Braid, Natural |

-4 |

100 ft |

919-5 |

SS Braid, Natural |

-5 |

Random |

919-5-100 |

SS Braid, Natural |

-5 |

100 ft |

919-6 |

SS Braid, Natural |

-6 |

Random |

919-6-100 |

SS Braid, Natural |

-6 |

100 ft |

919-8 |

SS Braid, Natural |

-8 |

Random |

919-8-100 |

SS Braid, Natural |

-8 |

100 ft |

919B-4 |

SS Braid, Static Dissipative |

-4 |

Random |

919B-5 |

SS Braid, Static Dissipative |

-5 |

Random |

919B-6 |

SS Braid, Static Dissipative |

-6 |

Random |

919B-8 |

SS Braid, Static Dissipative |

-8 |

Random |

919BJ-10-ORG |

Silicone Jacket, Static Dissipative |

-10 |

Random |

919BJ-12-ORG |

Silicone Jacket, Static Dissipative |

-12 |

Random |

919BJ-16-ORG |

Silicone Jacket, Static Dissipative |

-16 |

Random |

919BJ-4-ORG |

Silicone Jacket, Static Dissipative |

-4 |

Random |

919BJ-5-ORG |

Silicone Jacket, Static Dissipative |

-5 |

Random |

919BJ-6-ORG |

Silicone Jacket, Static Dissipative |

-6 |

Random |

919BJ-8-ORG |

Silicone Jacket, Static Dissipative |

-8 |

Random |

919J-10-RED |

Silicone Jacket, Natural |

-10 |

Random |

919J-12-RED |

Silicone Jacket, Natural |

-12 |

Random |

919J-16-RED |

Silicone Jacket, Natural |

-16 |

Random |

919J-4-RED |

Silicone Jacket, Natural |

-4 |

Random |

919J-5-RED |

Silicone Jacket, Natural |

-5 |

Random |

919J-6-RED |

Silicone Jacket, Natural |

-6 |

Random |

919J-8-RED |

Silicone Jacket, Natural |

-8 |

Random |

919U-12 |

Polyurethane Jacket, Natural |

-12 |

Random |

919U-16 |

Polyurethane Jacket, Natural |

-16 |

Random |

919U-4 |

Polyurethane Jacket, Natural |

-4 |

Random |

919U-6 |

Polyurethane Jacket, Natural |

-6 |

Random |

919U-8 |

Polyurethane Jacket, Natural |

-8 |

Random |

为什么要使用派克919软管?

耐化学腐蚀的PTFE-聚四氟乙烯光滑管软管-919 / 919B / 919J / 919U

派克919系列软管的小壁厚为.030英寸PTFE,可承受苛刻的化学药品和高温。工业界通常使用该软管,因为它符合SAE或FDA标准,尽管由于PTFE内管具有耐用性和使用寿命,所以有些人只是简单地使用它。随着时间的流逝,如果材料的设计不能承受特定的介质,则苛刻的化学药品和油类基本上会侵蚀内管。一旦内管破裂,流体就可以开始通过金属加固夹套吞噬。经过足够的时间后,软管可能会从盖上吞下。显然,如果您要处理潜在的环境和健康危害,那就不好了。

哪种PTFE软管适合我的应用?

919软管有4种类型,每种类型各有特点。我们将为您分解它们。

919 / 919B软管

919 / 919B软管的工业用途包括化学药品,液压油,压缩空气和气体以及冷却剂的输送。919和919B软管实际上是相同的,除了一个主要区别。919软管的内管是符合FDA的天然PTFE材料,而919B型软管则具有黑色的静电消散芯管。因此,在输送非导电介质(如油,油漆,燃料,蒸汽等)时,应使用919B软管。

内胎:919 –符合FDA的天然PTFE | 919B –黑色防静电PTFE增强材料:304不锈钢编织层

工作参数

温度范围: -100°F(-73℃)至450 +°F(232℃)

变化的长度为大。工作压力:

小+ 2%至-4%爆破压力是大的4倍。23°C(73°F)下的工作压力

资质认证

达到/超过SAE 100R14A(919)

达到/超过SAE 100R14B(919B)

FDA 21 CFR 177.1550(919天然管)

919J系列软管

如果保护层很重要,则919J软管是更好的选择。它有一个硅胶套,可以保护不锈钢丝增强件免受磨损。它还可以防止外部污染物进入传输线。

内管:919 –符合FDA的天然PTFE增强材料:304不锈钢编织层盖:挤压硅胶

工作参数

温度范围: -40°F(-40°C)至+ 450°F(232°C)的

大长度变化 工作压力:

小+ 2%至-4%爆破压力是大的4倍。23°C(73°F)下的工作压力

资质认证

达到/超过SAE 100R14A

FDA 21美国联邦法规177.1550

919U系列软管

与919J软管相比,该系列软管提供了更持久的抗磨损和抗污染的外层保护。与有机硅相反,该覆盖层是无磨损,耐磨的聚氨酯覆盖层。由于这一特性,如果温度可能超过275°F,则不适合使用919U软管。

内管:919 –符合FDA的天然PTFE增强材料:304不锈钢编织层盖:聚氨酯

工作 参数

温度范围: -40°F(-40℃)至+ 275°F(135℃)

变化的长度为大。工作压力:

小+ 2%至-4%爆破压力是大的4倍。23°C(73°F)下的工作压力

资质认证

达到/超过SAE 100R14A

FDA 21美国联邦法规177.1550

PTFE一般指聚四氟乙烯。聚四氟乙烯(Poly tetra fluoroethylene,简写为PTFE)

Parker 919 Hose - Why use Parker 919 Hose?

Parker 919 series hose is constructed with minimum .030″ PTFE tube wall to withstand both harsh chemicals and high temperatures. Industries commonly use this hose because it complies with SAE or FDA standards, although some simply use it because of the durability and longevity the PTFE inner tube provides. Over time, harsh chemicals and oils essentially eat away at the inner tube if the material is not designed to withstand that particular media. Once the inner tube breaks down, the fluid can begin to eat through the metal reinforcement jacket. After enough time goes by, the hose could eat through the cover. Obviously, not good if you’re dealing with potential environmental and health hazards.

Which PTFE hose is right for my application?

There are 4 types of 919 hose, each with their own distinct characteristics. We’ll break them down for you.

919/919B Hose

Parker 919 hoseIndustry uses for 919/919B hose include the transfer of chemicals, hydraulic fluids, compressed air & gas, and coolants. 919 and 919B hose are virtually identical with the exception of one major difference. The inner tube for 919 hose is a natural FDA compliant PTFE material while 919B type hose has a black static-dissipative core tube. For this reason, you should use 919B hose when conveying non-conducting media such as oils, paints, fuels, steam, and so on.

Inner tube: 919 – Natural FDA Compliant PTFE | 919B – Black Static-Dissipative PTFE Reinforcement: 304 stainless steel braid

Operating Parameters

Temperature Range: -100°F (-73°C) to +450°F (232°C)

Change in length at Max. Working Pressure: +2% to -4%

Min. Burst Pressure is 4x Max. Working Pressure at 73°F (23°C)

Certifications

Meets/Exceeds SAE 100R14A (919)

Meets/Exceeds SAE 100R14B (919B)

FDA 21 CFR 177.1550 (919 Natural tube)

919J Series Hose

Parker 919J hose with silicone cover919J hose is the better option if an outer layer of protection is important. It has a silicone cover to protect the stainless steel wire reinforcement from fraying. It also prevents external contaminants from entering the transfer line.

Inner tube: 919 – Natural FDA Compliant PTFE Reinforcement: 304 stainless steel braid Cover: Extruded silicone

Operating Parameters

Temperature Range: -40°F (-40°C) to +450°F (232°C)

Change in length at Max. Working Pressure: +2% to -4%

Min. Burst Pressure is 4x Max. Working Pressure at 73°F (23°C)

Certifications

Meets/Exceeds SAE 100R14A

FDA 21 CFR 177.1550

919U Series Hose

Parker 919U hose for abrasion resistance

series hose provides a more durable outer layer of protection against fraying and contaminants than 919J hose. The cover is a non-marring, abrasion resistant polyurethane cover, as opposed to silicone. Due to this characteristic, 919U hose is not suitable for use if temperatures could exceed 275°F.

Inner tube: 919 – Natural FDA Compliant PTFE Reinforcement: 304 stainless steel braid Cover: Polyurethane

Operating Parameters

Temperature Range: -40°F (-40°C) to +275°F (135°C)

Change in length at Max. Working Pressure: +2% to -4%

Min. Burst Pressure is 4x Max. Working Pressure at 73°F (23°C)

Certifications

Meets/Exceeds SAE 100R14A

FDA 21 CFR 177.1550

|