Eaton's Aluminium Flat Face ADB coupling 干式平面快速接头

ADB Series Aluminium Flat Face / Dry Break Coupling

Hansen Eaton ADB series dry-break aluminium couplings for fluid transfer

ADB series aluminium coupling is a flat face/dry break coupling

伊顿的平面铝材质ADB接头是一种平面/干式快速接头,用于循环水和防冻液的电力应用中的冷却系统。这种耦合提供了一种增强的解决方案,可防止冷却剂溢出,从而导致技术故障、系统关闭和难以清理。Eaton's Aluminium Flat Face ADB coupling is a flat face/dry break coupling used for cooling systems in electric applications with circulating water and antifreeze fluids. This coupling is providing an enhanced solution for preventing spillage of cooling agent which can cause technical failures, system shutdowns, and difficult clean-ups.

Eaton's Aluminium Flat Face ADB coupling 干式平面快速接头

ADB Series (Aluminium) Flat Face / Dry Break Coupling

性能特点

- 铝制结构延长了使用寿命,使操作更安全,减少了维护。

Aluminium construction extends life for safer operations and reduced maintenance.

- 与塑料快速接头相比,增强了在具有热和振动的苛刻应用中的操作。

Enhances operations in demanding applications with heat and vibration compared to plastic couplings.

- 高达62%的流量比ISO 16028要求,以提高效率。

Up to 62% higher flow than ISO 16028 requirements to improve efficiency.

- 工作压力为25bar时的4倍安全系数。

4-times safety factor at maximum operating pressure of 25 bar.

- 根据EN 61373的规定,增强型抗振动试验可用于铁路应用。

Options are available for railway applications with an enhanced version for vibration resistance tested according to EN 61373.

- 预先引导系统,帮助用户在困难的环境中预先定位耦合,使连接更容易,并减少维护时间。

Pre-guided system that helps users pre-position the coupling in difficult environments, making connection easy and reducing maintenance time.

- 全系列可选密封件、端部连接和尺寸,帮助制造商从任何类型的应用中受益。

Full range of optional seals, end connections and sizes, helping manufacturers benefit from the design in any type of application.

产品特点 -

Applications & Markets

- 电子设备液体冷却应用

Electrical cooling applications

- 可再生能源

Renewable energy

- 铁路 Railway

- 加工业 Processing industry

- 数据中心 Datacenters

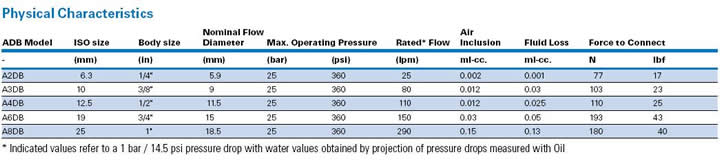

Physical Characteristics

ADB Model ISO size Body size

Nominal Flow

Diameter Max. Operating Pressure Rated* Flow

Air

Inclusion Fluid Loss Force to Connect

- (mm) (in) (mm) (bar) (psi) (lpm) ml-cc. ml-cc. N lbf

A2DB 6.3 1/4" 5.9 25 360 25 0.002 0.001 77 17

A3DB 10 3/8" 9 25 360 80 0.012 0.03 103 23

A4DB 12.5 1/2" 11.5 25 360 110 0.012 0.025 110 25

A6DB 19 3/4" 15 25 360 150 0.03 0.05 193 43

A8DB 25 1" 18.5 25 360 290 0.15 0.13 180 40

* Indicated values refer to a 1 bar / 14.5 psi pressure drop with water values obtained by projection of pressure drops measured with Oil

Seal Elastomer Data*

Seal Elastomer Max. Operation Temperature Range

FKM -20°C +200°C/-4°F +392°F

EPDM (Ethylene-Propylene) -40°C +150°C/-40°F +302°F

Kalrez? 6375 -20°C +275°C/-4°F +527°F

Generic FFKM (Perfluorocarbon) -15°C +275°C/+5°F +527°F

* For reference only, based on Eaton recommended temperatures.

Contact Eaton technical support for further information on fluid compatibility

Flow Data

47

PNEUMATIREFRIGERANT AGRICULTURE DIAGNOSTIC SPECIAL APPLICATIONS C FLUID TRANSFER

AND HYDRAULIC

EATON Quick Disconnect Couplings EMEA E-MEQD-CC002-E4 December 2018

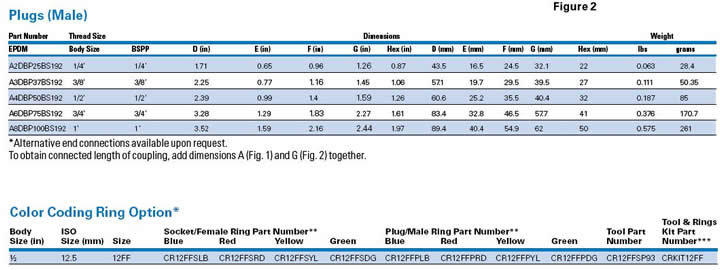

Color Coding Ring Option*

Tool & Rings

Kit Part

Number***

Body

Size (in)

ISO

Size (mm)

Socket/Female Ring Part Number** Plug/Male Ring Part Number** Tool Part

Size Blue Red Yellow Green Blue Red Yellow Green Number

? 12.5 12FF CR12FFSLB CR12FFSRD CR12FFSYL CR12FFSDG CR12FFPLB CR12FFPRD CR12FFPYL CR12FFPDG CR12FFSP93 CRKIT12FF

For color coded rings TPE material is used that offers excellent flexibility which allows a very good shock resistance in demanding applications.

Good thermal, chemical and weather resistance provides a great fit on the coupling and a extended life time in toughest conditions.

The color coded rings are easy to install by using the referenced tools. Please refer to the user guide on “eaton.com”

* For requests on alternative colors or installation instructions, please contact your Eaton sales representative.

** Orders must be in multiples of 10 pcs.

*** The kit consists of a tool plus 10 socket rings and 10 plug rings of each color.

ADB Series (Aluminium)

Flat Face/Dry Break

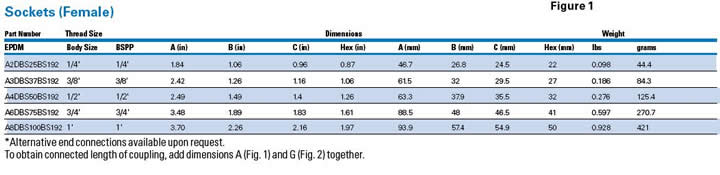

Sockets (Female)

Part Number Thread Size Dimensions Weight

EPDM Body Size BSPP A (in) B (in) C (in) Hex (in) A (mm) B (mm) C (mm) Hex (mm) lbs grams

A2DBS25BS192 1/4' 1/4' 1.84 1.06 0.96 0.87 46.7 26.8 24.5 22 0.098 44.4

A3DBS37BS192 3/8' 3/8' 2.42 1.26 1.16 1.06 61.5 32 29.5 27 0.186 84.3

A4DBS50BS192 1/2' 1/2' 2.49 1.49 1.4 1.26 63.3 37.9 35.5 32 0.276 125.4

A6DBS75BS192 3/4' 3/4' 3.48 1.89 1.83 1.61 88.5 48 46.5 41 0.597 270.7

A8DBS100BS192 1' 1' 3.70 2.26 2.16 1.97 93.9 57.4 54.9 50 0.928 421

| Body Size |

Part Number (with EPDM Seal) |

Part Number (with FKM Seal) |

BSP |

Coupling Type |

| 1/4 |

A2DBS25BS192 |

A2DBS25BS143 |

1/4 |

Socket |

| 1/4 |

A2DBP25BS192 |

A2DBP25BS143 |

1/4 |

Plug |

| 3/8 |

A3DBS37BS192 |

A3DBS37BS143 |

3/8 |

Socket |

| 3/8 |

A3DBP37BS192 |

A3DBP37BS143 |

3/8 |

Plug |

| 1/2 |

A4DBS50BS192 |

A4DBS50BS143 |

1/2 |

Socket |

| 1/2 |

A4DBP50BS192 |

A4DBP50BS143 |

1/2 |

Plug |

| 3/4 |

A6DBS75BS192 |

A6DBS75BS143 |

3/4 |

Socket |

| 3/4 |

A6DBP75BS192 |

A6DBP75BS143 |

3/4 |

Plug |

| 1 |

A8DBS100BS192 |

A8DBS100BS143 |

1 |

Socket |

| 1 |

A8DBP100BS192 |

A8DBP100BS143 |

1 |

Plug |

*Alternative end connections available upon request.

To obtain connected length of coupling, add dimensions A (Fig. 1) and G (Fig. 2) together.

Figure 1

Figure 2

Plugs (Male)

Part Number Thread Size Dimensions Weight

EPDM Body Size BSPP D (in) E (in) F (in) G (in) Hex (in) D (mm) E (mm) F (mm) G (mm) Hex (mm) lbs grams

A2DBP25BS192 1/4' 1/4' 1.71 0.65 0.96 1.26 0.87 43.5 16.5 24.5 32.1 22 0.063 28.4

A3DBP37BS192 3/8' 3/8' 2.25 0.77 1.16 1.45 1.06 57.1 19.7 29.5 39.5 27 0.111 50.35

A4DBP50BS192 1/2' 1/2' 2.39 0.99 1.4 1.59 1.26 60.6 25.2 35.5 40.4 32 0.187 85

A6DBP75BS192 3/4' 3/4' 3.28 1.29 1.83 2.27 1.61 83.4 32.8 46.5 57.7 41 0.376 170.7

A8DBP100BS192 1' 1' 3.52 1.59 2.16 2.44 1.97 89.4 40.4 54.9 62 50 0.575 261

*Alternative end connections available upon request.

To obtain connected length of coupling, add dimensions A (Fig. 1) and G (Fig. 2) together.

FLUID TRANSFER

AND HYDRAULIC PNEUMATIC SPECIAL APPLICATIONS DIAGNOSTIC AGRICULTURE REFRIGERANT EATON Quick Disconnect Couplings EMEA E-MEQD-CC002-E4 December 2018

|