|

下一代干式快速接头功能创新的球阀设计,使液体输送在制药应用更高效

Next-generation Dry Disconnect Coupling feature an innovative ball-valve design that enables the optimization of liquid transfer in pharmaceutical application.

- by David Gibble, Product Manager, Chemical & Industrial Business Unit, for OPW Engineered Systems

建立一个成功的制药生产运营的关键,可能就如同坚持一对熟悉的、由来已久的陈词滥调:“宁安全不后悔”和“时间就是金钱”一样基本。把一种药品的终产品从研发实验室拿到消费者手中并不容易,但如果处理的原材料和终产品中有许多必须包含或必须包含,挥发性或危险化合物在安全的同时,遵循一个简化的生产计划,可以大限度地从盈利的窗口的回报。

The keys to establishing a successful pharmaceutical-manufacturing operation may be as basic as adhering to a pair of familiar, time-honored clichés: “better safe than sorry” and “time is money.” Sure, taking a pharmaceutical end product from the R&D lab to the hands of the consumer isn’t easy, but the process can be optimized if the raw materials and end products that are handled—many of which necessarily are, or must contain, volatile or hazardous compounds—are done so safely while simultaneously following a streamlined manufacturing schedule that can maximize the returns from profitable patent windows.

然而,要在医药制造领域找到涅盘,需要简洁可靠地完成许多具体步骤。在这个过程中转移液体。有许多转运点,从原材料通过卡车或轨道车到达制造厂开始,然后通过各种管道和切换歧管,便于储存、加药、混合、混合、搬运、装瓶,以及构成生产和供应链许多环节的包装阶段。

Finding that nirvana in pharmaceutical manufacturing space, however, requires a lot of specific steps to be completed succinctly and reliably. Take the transfer of liquids in the process. There are many transfer points, starting when raw materials arrive at the manufacturing facility via truck or railcar, then through the various piping and switching manifolds that facilitate the storage, dosing, blending, mixing, tote-filing, bottling, and packaging stages that make up the many links in the production and supply chain.

在整个液体转移过程中,制药企业希望优化两个关键问题:生产人员和环境的安全以及完成制造过程所需的时间。

Throughout the liquid-transfer processes, pharmaceutical manufacturers are hoping to optimize two critical things: the safety of production personnel and the environment and the time needed to complete the manufacturing process.

确保人身和环境安全非常重要,因为制药生产中使用的许多原材料可能是挥发性、危险性或腐蚀性化合物,如甲苯、二氯甲烷、氨、不同的泥浆和钾盐,例如,它们必须被适当地控制。毕竟,制药企业之间有句俗话:“每家制药厂不过是一家化工厂。”

Ensuring personal and environmental safety is important because many of the raw materials used in pharmaceutical manufacture can be volatile, hazardous, or corrosive—compounds such as toluene, dichloromethane, ammonia, different slurries, and Syltherm, for example—so they must be properly contained. After all, there is a common saying among pharmaceutical manufacturers: “every pharmaceutical plant is nothing more than a chemical plant.”

此外,防止溢出或泄漏至关重要,因为任何发生的事件,除了在不同程度上具有危险性外,还可能中断生产进度,这不仅会延迟产品完成,还会导致高价值的损失,昂贵的原料和高昂的清理费用。

Additionally, preventing spills or leaks is vital because any that occur, besides being dangerous on various levels, have the potential to interrupt the production schedule, which not only delays product completion, but can also lead to the loss of high-value, expensive ingredients and the incurrence of prohibitive cleanup costs.

Pharmaceutical manufacturing requires the precise handling and dosing of both high-value and hazardous raw materials and end products, necessitating the need for dry disconnect coupling technology that provides a consistent flow rate with little chance of product spills or leaks. The Epsilon Dry Disconnect Coupling from OPW Engineered Systems meets those needs thanks to its innovative ball-valve design.制药制造需要对高价值和危险的原材料和终产品进行精确的处理和加药,因此需要采用干式断开连接技术,这种技术能够提供一致的流速,而产品泄漏或泄漏的可能性很小。Epsilon干式快速接头,opw工程系统满足这些需要,感谢其创新的球阀设计。

制药制造需要对高价值和危险的原材料和终产品进行精确的处理和加药,因此需要采用干式断开连接技术,这种技术能够提供一致的流速,而产品泄漏或泄漏的可能性很小。Epsilon干式快速接头,opw工程系统满足这些需要,感谢其创新的球阀设计。

Pharmaceutical manufacturing requires the precise handling and dosing of both high-value and hazardous raw materials and end products, necessitating the need for dry disconnect coupling technology that provides a consistent flow rate with little chance of product spills or leaks. The Epsilon Dry Disconnect Coupling from OPW Engineered Systems meets those needs thanks to its innovative ball-valve design.

OPW Epsilon low-spill dry disconnect coupling Video

Taking the Plunge

多年来,当制药商正在寻找一种干式断开技术时,一种特定类型的技术已经成为主流,这种技术将在液体转移过程中连接到卡车、轨道车、歧管和管道上的各种软管。这种技术被称为“卡口和柱塞”或“提升阀”式连接器。Over the years, a certain type of technology has risen to the fore when pharmaceutical manufacturers are looking for a dry disconnect technology to implement with the various hoses that will be attached to trucks, railcars, manifolds, and pipes during the liquid-transfer process. This technology is referred to as either a “bayonet-and-plunger” or “poppet” style coupler.

卡口柱塞式干式断开车钩技术由于其设计和使用对用户有诸多好处而得到了认可。重要的是,当连接器断开时,液体损失相对较小,仅为0.5毫升(ml),或相当于1/10茶匙(约0.017盎司)的液体。它们通常还配有安全锁,以防止流体流过连接器时连接器意外打开。The bayonet-and-plunger dry disconnect coupler technology has gained acceptance because its design and operation possesses a number of benefits for the user. Most important, there is relatively little fluid loss when the coupler is disconnected, as little as 0.5 milliliter (ml) of fluid, or the equivalent of 1/10th of a teaspoon, which is approximately 0.017 of an ounce. They are also generally equipped with safety locks that prevent the coupler from opening accidentally as fluid is flowing through it.

大多数品牌的卡口和柱塞耦合器重量轻,易于操作,消除了操作人员的操作应力和应力。它们的低成本也使它们对那些希望精简资本成本并保护运营底线的制造商具有吸引力。Most brands of bayonet-and-plunger couplers are lightweight and easy to maneuver, which eliminates undo operational stress and strain on the operator. Their low cost also makes them attractive to manufacturers who are looking to streamline capital costs and protect the operation’s bottom line.

尽管如此,卡口和柱塞连接器确实具有一些负面的操作特性,这使得它们无法成为制药应用中的干式断开耦合器技术选择。首先,虽然在断开过程中可能会损失极少量的油液,但也有其他耦合技术会损失较少的油液。With all that being said, bayonet-and-plunger couplers do have a number of negative operational characteristics that prohibit them from being the absolute best dry disconnect coupler technology choice in pharmaceutical-manufacturing applications. First, while an extremely small amount of fluid may be lost during disconnection, there are other coupler technologies that will lose lesser amounts of fluid.

从操作的角度来看,卡口和柱塞连接器的不足是其设计,它使许多内部零件与流体直接接触。任何类型的流量限制都会对生产过程产生负面影响。例如,如果工程师指定了一条2“管线,并且安装了带有2”内径的卡口和柱塞连接器,实际上,流量将小于从自由流2“管线预期的流量,因为液体必须围绕其接触的连接器部件工作。这也可能需要一个大于所需的2.5“和3”耦合器。

From an operational standpoint, the biggest shortfall of bayonet-and-plunger couplers is their design, which puts a number of internal parts in direct contact with the fluid flow. Any type of flow-rate restriction will negatively affect the production process. For example, if an engineer specifies a 2” line and a bayonet-and-plunger coupler with a 2” I.D. is installed, the flow rate will actually be less than what is to be expected from a free-flow 2” line because the liquid will have to work its way around the coupler parts that it comes into contact with. This may also necessitate the need for a larger-than-necessary 2.5” and 3” coupler.

此外,卡口和柱塞连接器的内部组件,如弹簧、导向器和提升阀,也会产生液体聚集和隐藏的区域,这使得清洁管路和保持卫生的泵送环境变得困难。Additionally, the bayonet-and-plunger coupler’s internal components, things such as springs, guides and poppets, can also create areas where the liquid can collect and hide, which makes it difficult to clean the lines and maintain a sanitary pumping environment.

当制造商选择采用闭环流体输送系统时,刺刀和柱塞耦合器可能处于不利地位,而闭环流体输送系统在制药生产过程中正变得越来越流行。缺点是,在一个闭环系统中,可能会有许多阀门展开,这意味着在某一点上,两个阀门的关闭将使产品困在关闭阀门之间的软管中。下游阀门随后打开时产生的压力有可能损坏前面的连接器,从而导致泄漏和产品泄漏。Bayonet-and-plunger couplers can be at a disadvantage when manufacturers choose to incorporate a closed-loop fluid-transfer system, which is becoming more popular in pharmaceutical-manufacture processes. The drawback is that in a closed-loop system there may be numerous valves deployed, meaning that at some point the closing of two valves will leave product trapped in the hose between the closed valves. The pressure that is created when the downstream valve is subsequently opened has the potential to damage the coupler ahead of it, which can lead to leaks and product spills.

后,由于卡口和柱塞耦合器包含的零件数量较多,因此很难在线维修或维护。事实上,许多卡口和柱塞供应商要求拆下连接器并将其退回制造商进行维修。如果车钩可以在现场维修,所需步骤的数量和要考虑的零件数量可能会使维修技师感到困难或困惑。Lastly, bayonet-and-plunger couplers are harder to repair or maintain inline because of the number of parts they contain. In fact, many bayonet-and-plunger suppliers require the coupler to be removed and returned to the manufacturer for repairs. If the coupler can be repaired in the field, the number of steps required and number of parts to consider can make it difficult or confusing for the maintenance technician.

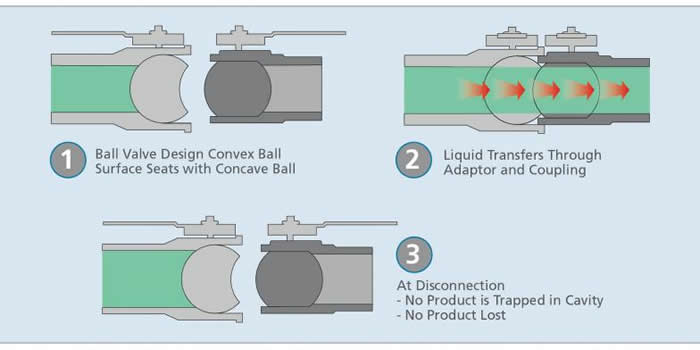

Caption: The unique ball-valve operation of the OPW Epsilon Dry Disconnect Coupling allows a convex ball to seat with a concave ball when the valve is opened, in the process creating a straight-through flow path with no cavities or crevices where product can rest. Conversely, the design of traditional poppet-style dry disconnects allows a small amount of liquid to be trapped during disconnection, which can lead to spills that can be harmful to site personnel and the environment.描述:OPW Epsilon干式断开接头的独特球阀操作允许在阀门打开时凸球与凹球一起落座,在这一过程中,形成了一条无空腔或裂缝的直通流道,产品可在此处停留。相反,传统的提升阀式干式断开装置的设计允许在断开期间截留少量液体,这可能导致泄漏,对现场人员和环境有害。

描述:OPW Epsilon干式断开接头的独特球阀操作允许在阀门打开时凸球与凹球一起落座,在这一过程中,形成了一条无空腔或裂缝的直通流道,产品可在此处停留。相反,传统的提升阀式干式断开装置的设计允许在断开期间截留少量液体,这可能导致泄漏,对现场人员和环境有害。Caption: The unique ball-valve operation of the OPW Epsilon Dry Disconnect Coupling allows a convex ball to seat with a concave ball when the valve is opened, in the process creating a straight-through flow path with no cavities or crevices where product can rest. Conversely, the design of traditional poppet-style dry disconnects allows a small amount of liquid to be trapped during disconnection, which can lead to spills that can be harmful to site personnel and the environment.

A Better Solution 更好的解决办法

多年来,卡口式和柱塞式干式断开耦合器在医药制造业的应用中取得了令人钦佩的成绩,但一种新型干式断开耦合器技术已经出现,它能够克服在提升式耦合器中发现的缺点。下一代耦合器技术通过创新的双球阀设计,而不是卡口和柱塞。While bayonet-and-plunger dry disconnect couplers have performed admirably in pharmaceutical-manufacturing applications over the years, a new dry disconnect coupler technology has emerged that is able to overcome the shortcomings found in poppet-style couplers. This next-generation coupler technology operates via an innovative double-ball-valve design, rather than bayonet-and-plunger.

该设计的特点是一个凸球位于凹球内,从而消除了两半配合之间的任何空腔,并保证不会有残留液体被困在那里,降低了溢出的风险,使液体几乎没有地方收集或隐藏,方便清洁,提高卫生操作水平。具体地说,断开连接后,在连接器的密封面上留下的液体少于0.5毫升,少于泪滴的四分之一。The design features a convex ball that rests in a concave ball, resulting in the elimination of any cavity between the mating halves and guaranteeing that no residual fluid will be trapped there, lowering the risk of spills and giving the liquid virtually no place to collect or hide, which eases cleaning and raises the level of sanitary operation. Specifically, upon disconnection, there will be less than 0.5 ml of fluid left on the face seal of the coupler, an amount that is less than one-quarter of a teardrop.

球阀的设计还包括多个安全联锁装置,允许阀门仅通过用户的故意操作打开和关闭。这样可以防止阀门意外打开,从而降低意外泄漏和灾难性化学品泄漏的风险。这不仅在从大型储存容器中转移原材料时是至关重要的,而且在作为药品制造的主要原料的许多手提袋填充操作中也是如此。这种小容量容器的恒定开、关充可以消除耦合器上的应力,但球阀的设计和操作方法消除了有害影响。The ball-valve design also incorporates multiple safety interlocks that allow the valve to open and close only through a deliberate action by the user. This prevents any accidental opening of the valve, which lowers the risk of unintentional spills and catastrophic chemical releases. This is not only critical when transferring raw materials from large storage vessels, but also during the numerous tote-filling operations that are a staple of pharmaceutical manufacture. This constant on-and-off filling of smaller-capacity vessels can put undo strain on the couplers, but the ball-valve design and method of operation nullify the harmful effects.

这些新的耦合器可以帮助提高安全性的另一种方法是,事实上,耦合器的表面密封(在符合fda标准的tfm或pda中提供)比竞争技术更耐磨。任何落在密封件上的砂砾、污垢或微粒都有可能留下划痕,划痕可能会造成泄漏路径。由于端面密封具有较高的耐磨性,因此形成划痕引起泄漏路径的可能性小。Another way these new couplers can help improve safety is found in the fact that the coupler’s face seal—which is available in FDA-compliant TFM or PDA—is more resistant to abrasion than competitive technologies. Any grit, dirt, or particulates that get on the seal have the potential to leave scratches, with the scratches capable of creating leak paths. Because the face seals have a higher level of abrasion resistance, the chance of scratch-induced leak paths being formed is minimized.

球阀的设计也创造了一个不受限制的流动路径,使压降小化,在150加仑/分钟(568升/分钟)的流速下,压降小于1 psi。换言之,需要2“软管的液体输送系统可以使用2”球阀耦合器模型,而无需降低或限制所需的流量。The ball-valve design also creates an unrestricted flow path, which minimizes pressure drop and results in less than 1 psi in pressure drop at a flow rate of 150 gallons per minute (568 liters per minute). In other words, a liquid-transfer system that calls for a 2” hose can utilize a 2” ball-valve coupler model without any reduction or restriction to the required flow rate.

与卡口式和柱塞式相比,这种新型球阀连接器的终优点是易于维护。由于其零部件比竞争对手的技术少,所以球阀车钩的现场维修非常容易,无需将车钩退回厂家或现场维修人员,与复杂而混乱的维修或保养说明书作斗争。The final benefit of the new ball-valve coupler when compared to its bayonet-and-plunger cousins is its ease of maintenance. Because it has fewer parts than competitive technologies, the ball-valve coupler can be repaired on-site very easily, with no need to return the coupler to the manufacturer or in-the-field repair personnel to battle with complicated and confusing repair or maintenance instructions.

The unrestricted flow path of the OPW Epsilon Dry Disconnect Coupling enables pharmaceutical manufacturers to experience optimized loading and unloading times.

Conclusion

实现安全操作和成本效益是制药企业面临的一项日常挑战,尤其是当所用原材料既危险又昂贵时。由于许多生产作业需要大型罐区,每天要转移数千加仑的原材料和终产品,因此使用的干式断开耦合器的类型以及该技术优化安全性和成本的能力是一个关键问题。Achieving safe operation and cost-effectiveness is a day-to-day challenge for pharmaceutical manufacturers, especially when the raw materials used are both hazardous and expensive. With many production operations requiring large tank farms and the transfer of thousands of gallons of raw materials and end products on a daily basis, the type of dry disconnect coupler used, and the technology’s ability to optimize safety and cost is a critical concern.

虽然传统的耦合器技术已被证明能有效地满足液体输送的基本需求,但通过使用新一代技术,如球阀干式断开耦合器,这一过程可以提升到下一个层次。这项技术提供了可靠、安全、无泄漏的产品控制、全流量能力、法规遵从性以及易于维修和维护的操作优势,使制药商能够满足其安全和及时生产的需要。While legacy coupler technologies have proven to be effective in meeting the basic needs of liquid transfer, the process can be taken to the next level with the use of a next-generation technology like the ball-valve dry disconnect coupler. This technology provides the operational advantages—reliable, safe, and leak-free product containment; full-flow capability; regulatory compliance; and ease of repair and maintenance—that will enable pharmaceutical manufacturers to meet their needs regarding safety and timely production.

About the Author

David Gibble is Product Manager, Chemical & Industrial Business Unit, for OPW Engineered Systems, part of Dover Corporation’s OPW division. He can be reached at (800) 547-9393 or dgibble@opw-es.com. OPW is the global leader in fully integrated fluid-handling, management, monitoring, and control solutions for the safe and efficient handling of critical petroleum-derived fluids from the refinery to the commercial and retail points of consumption, including loading systems, rail and transport tank-truck equipment, tank-gauging equipment, and automated fuel-management systems, valves and fittings, underground and aboveground storage-tank equipment, spill containers, overfill-prevention devices, secondary-containment sumps and flexible piping, fuel-dispensing products, including swivels, breakaways, industrial and automatic dispensing nozzles for vapor recovery, gasoline, diesel and alternative fuels, and clean energy fueling nozzles and accessories for LPG, Hydrogen and CNG. OPW also manufactures automated vehicle wash systems. OPW has 1,650+ employees with manufacturing operations in North America, Europe, Brazil, China, and India and sales offices around the world. OPW is an operating company within the Fluids segment of Dover Corporation (NYSE: DOV).

Epsilon适用于危险性流体疏松的压降小的干式快换接头

Epsilon低泄露接头系统

EPSILON是一种经过精密安全设计的基于双球阀系统的低泄露接头。除了拥有球形阀设计所具备的共有优点之外,EPSILON接头还为管路连接中的流体提供一条自由流动通道,并且在接头连通时具有双重锁紧功能,增加系统的可靠性。EPSILON接头系统是为了用于避免化学制品的泄漏和减少挥发性有机化合物(VOC)的散逸性排放,尤其是在过程设备中和槽车装卸过程中。EPSILON化学制品存储系统可以为你的工厂在化学制品的输送过程提供更适应的工艺流程,如改善人员的安全性和降低环境污染的风险,并为您减少总的资金花费和降低运行成本。

EPSILON快换接头特点

- 提供3/4”, 1”, 1-1/2”, 2” 和3”规格

- 提供不锈钢和Hastelloy材质

- 适用的接口标准为ANSI美国标准和DIN欧洲标准。

- 符合标准的密封材料,TFM

Next generation PTFE with best combination of temperature ranging from -22°F (-30°C) to 450°F (230°C), sealing, and sliding characteristics.

- 设计的大工作压力为435 psi(30Bar),高温度可达450°F(230°C)

- 弹簧操动并加载的TFM或PFA U型杯密封结构

A spring-energized stem and face and flange seal provide initial sealing. The spring supplies all the load required for sealing when the media pressure is too low to fully actuate the lips of the seal. Testing confirms the low spillage and emission specifications are still achieved after 2,000 cycles.

- 聚氨酯防尘罩或不锈钢承压盖帽

Used to protect the ball from damage and debris when coupling is closed and disconnected.

- 外螺纹和内螺纹凸耳/法兰联接面

Ramped lug and flange interfaces are first aligned and then connected with a push, followed by a quarter (90°) turn. This “instant” connection method is done by hand without tools in order to create compression on the critical interface seal.

- 独立、多级安全联锁装置

EPSILON technology involves five independent and redundant mechanical interlocks. They require deliberate sequential action by users, thereby eliminating unintentional spills and catastrophic chemical releases that threaten worker safety and the environment.

- 经多家国际机构批准可用于各种承受压力的用途

|

![]()